FMH Conveyors

®

Operator’s Manual

NestaFlex 376PL Conveyors

11 |

P A G E

EFFECTIVE JUNE 2017 PART # 016842 ©2016 FMH CONVEYORS LLC

Your conveyor will require minimal maintenance under normal operating conditions. However, since

there are occasional problems with all equipment, the following paragraphs provide parts replacement

procedures.

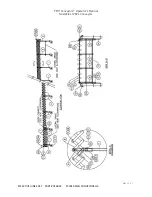

Elevation Adjustment

Tools and Parts Required: 5/32” Allen wrench, loctite

242 or equivalent

NOTE: On most gravity truck loader conveyors, height adjustments are unnecessary. The conveyor

height has been set at the factory for optimal product flow.

1.

Loosen the set screw on both vertical legs. The set screws are located on the lower cross brace.

2.

Raise the H Frame and conveyor to desired height.

3.

Apply loctite

to the threads of the set screw.

4.

Turn and tighten the set screws on both vertical legs.

Inner Leg/Caster Assembly Replacement

Tools and Parts required: ½” wrenches (2), 5/32” Allen wrench, Loctite

242 or equivalent, dimple lock

nuts (6), inner leg/caster.

1.

Move the conveyor off of the guide track.

2.

Identify the section of conveyor that contains the inner leg/caster to be replaced.

3.

Separate that conveyor section from the system by removing the quick connect fasteners. Retain

the fasteners for the re‐assembly process.

4.

Fully contract conveyor section.

5.

Carefully lay the conveyor section on its side.

6.

Loosen the set screw at the affected inner leg/caster.

7.

Remove the inner leg/caster by pulling it out of the H Frame outer leg.

8.

Insert the new inner leg/caster fully into H Frame outer leg.

9.

Apply loctite to the set screw and tighten it securely.

10.

Carefully return the conveyor to an upright position.

11.

Return the conveyor section to its correct location within the conveyor system.

12.

Push the conveyor sections together to align the holes in the quick connect plates.

13.

Insert the top screw on each side and add the washer and nut.

14.

Insert the two remaining screws on each side and add the washers and nuts.

15.

Securely tighten each fastener to make the connections permanent.

16.

Return the conveyor system onto the guide track.