FMH Conveyors

®

Operator’s Manual

NestaFlex 376PL Conveyors

13 |

P A G E

EFFECTIVE JUNE 2017 PART # 016842 ©2016 FMH CONVEYORS LLC

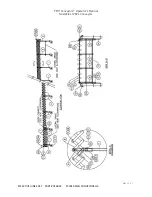

Nut, Screw, Washer Replacement

Tools and Parts required: ½” wrench, 7/16” wrench, hex shoulder screw, ¼‐20 hex dimple nut, and a

spring washer.

1.

Extend the conveyor to its fully open position. Remove

and discard the old nut, screw, and spring washer.

2.

Put the spring washer on the screw and insert the

screw through both side link holes.

NOTE: The spring washer (1) must be between the screw

hex head (2) and the side link (3) as shown at right.

3.

Thread a new nut onto the screw. Hold the screw

with the ½” wrench and tighten the nut (4), using the

7/16” wrench. Tighten to 70‐80 lb‐in (7.9 – 9.0 N‐m).

Shaft Replacement

Tools and Parts Required: Two ½” wrenches, a nylon lock nut, and a new shaft

NOTE: Some shafts may pass through other components, such as washers and spacers. Before removing

a shaft, make a note of the position of any such components. During reassembly, return these pieces to

their proper position to ensure the structural integrity and functionality of the conveyor.

1.

With the conveyor in the fully contracted position, use

the wrenches to remove and discard the nylon lock nut.

2.

Using the replacement shaft as a driver, carefully push

out and remove the damaged shaft. The replacement

shaft should now pass through all of the washers,

spacers, skate wheels, and links in their proper position.

3.

Install a new lock nut to complete the process.