Rev.4

3

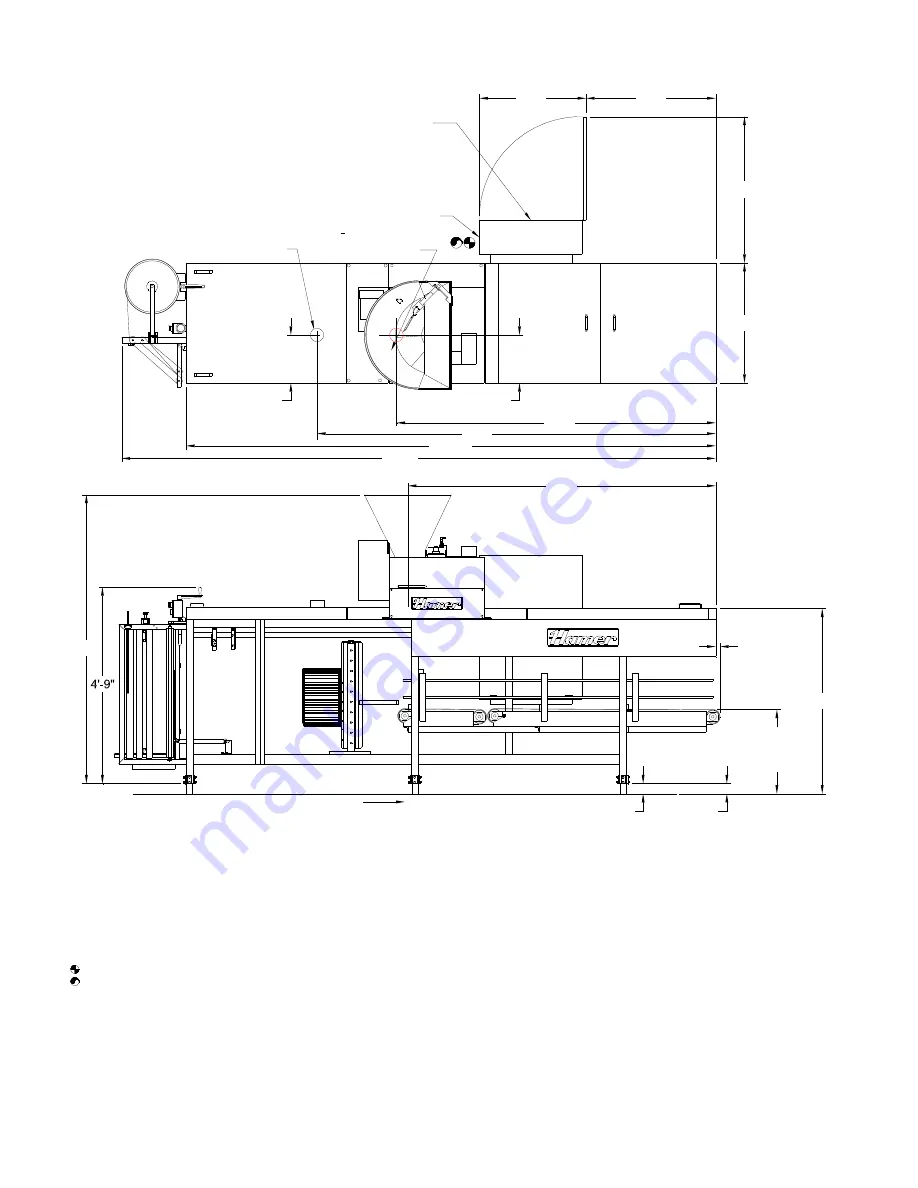

MACHINE LAYOUT

PRODUCT IN-FEED

2'-11"

2'-7"

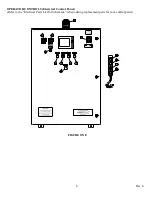

CONTROL PANEL

230VAC, 1-PHASE

60HZ, 46FLA

(OPTIONAL: 50HZ, 46FLA)

SEE NOTE 5

AIR IN

30 CFM @ 80 PSI

1

2

" LINE MINIMUM

EXAUST VENT

3'-7"

3'-2"

FEED DIRECTION

4'-6" REF.

9" MIN

30" MAX

SEE NOTE 1

7'-6"

NOTES:

1) ALL DIMENSIONS ARE IN INCHES.

2) THESE DIMENSIONS CHANGE ACCORDING TO BAG SIZE, AND

SOME ADJUSTMENTS MAY BE REQUIRED.

3) THE MACHINE SHOULD BE LOCATED WITH A MINIMUM OF 3 FT.

CLEARANCE ON ALL FOUR SIDES

4) ALL AIR INPUTS REQUIRE CLEAN DRY AIR.

5) DO NOT DRILL HOLES IN THE TOP OR ANY SIDE OF CONTROL PANEL.

ALL WIRES MUST GO IN THROUGH THE BOTTOM OF THE CONTROL

PANEL. ANY MODIFICATIONS TO THE CONTROL PANEL

WILL VOID MANUFACTURES WARRANTY!

6) OPTIONAL REMOTE INSTALLATION OF ELECTRICAL PANEL AVAILIBLE.

7) SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

*

AIR DROPS

ELECTRICAL DROPS

*

0" MIN.

2" MAX

SEE NOTE 1

0" MIN.

9" MAX.

*

*

*

1'-2"

FACTORY SET LEGS TO 3"

7'-9"

1'-2"

9'-8"

7'-0"

14'-5"

12'-10"

Summary of Contents for Hamer 540

Page 2: ......

Page 4: ......

Page 7: ...Rev 4 SECTION ONE MODEL 540 FORM FILL AND SEAL MACHINE...

Page 8: ......

Page 14: ......

Page 40: ...Rev 4 31 FIGURE EIGHT FIGURE NINE...

Page 47: ......

Page 55: ...Rev 4 45 SECTION TWO MODEL 540 ASSEMBLY DRAWINGS...

Page 56: ......