Rev.4

28

FILM CLAMP

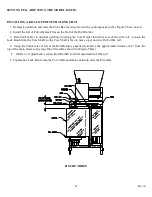

When the Film Feed Drive System stops, the Film Clamp Bar closes on the film, holding it in place.

At this point, all the force on the film is being confined to the Film Unwind area and not the Film Feed Drive

System.

The Film Clamp Bar must have a solid hold on the film along the full length of the bar. If not, loosen the two

Hex Head Bolts that mount the bottom of the Clamp Bar. Then slide the Clamp Pivot in either direction until the

Clamp Bar is flush with the film, then tighten the Hex Head Bolts

Start the machine and watch the Film Clamp in operation. Notice if there is clearance for the film to pass

through the Film Clamp. If the film hangs up on the Film Clamp, then slightly adjust the Clamp Pivot again to

achieve the clearance needed for free travel of the film.

CAUTION: TURN THE MAIN DISCONNECT ON THE CONTROL PANEL TO THE "OFF"

POSITION AND REMOVE THE AIR SUPPLY FROM THE MACHINE BEFORE MAKING

ADJUSTMENTS.

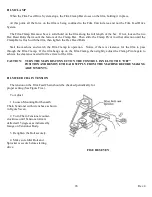

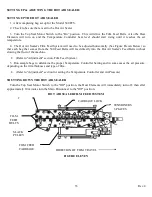

FILM FEED CHAIN TENSION

The tension on the Film Feed Chain should be checked periodically for

proper setting (See Figure Five).

To Adjust:

1. Loosen Mounting Bolt beneath

Chain Tensioner with wrenches as shown

in Figure Seven.

2. Turn Chain Tensioner counter-

clockwise until Tensioner Arm is

deflected 15 degrees as indicated by

Gauge on Tensioner Body.

3. Retighten the Bolt securely.

4. Make sure Idler Bolt and

Sprocket is secure before starting

drive.

FIGURE SEVEN

Summary of Contents for Hamer 540

Page 2: ......

Page 4: ......

Page 7: ...Rev 4 SECTION ONE MODEL 540 FORM FILL AND SEAL MACHINE...

Page 8: ......

Page 14: ......

Page 40: ...Rev 4 31 FIGURE EIGHT FIGURE NINE...

Page 47: ......

Page 55: ...Rev 4 45 SECTION TWO MODEL 540 ASSEMBLY DRAWINGS...

Page 56: ......