Rev.4

32

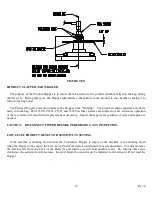

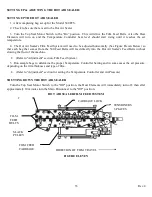

FIGURE TEN

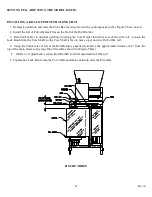

PRODUCT SLAPPER AND WIGGLER

The purpose of the Product Slapper is to insure that all product in the product chamber falls into the bag during

the fill cycle. During this cycle, the Slapper administers a sharp blow to the product in the chamber, causing it to

fall into the bag below.

The Product Wiggler prevents product in the Hopper from "bridging". The product remains separate and flows

easily into the bag. Parts #3199, #3201, #3281 and #3286 on these systems are subject to wear, and noisy operation

of these systems will result when replacement is necessary. Inspect these parts for evidence of wear and replace as

needed.

CAUTION: DISCONNECT POWER BEFORE PERFORMING ANY INSPECTION.

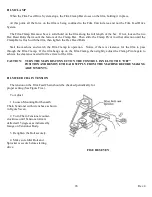

LOW LEVEL PRODUCT DETECTOR SENSITIVITY SETTING

If the machine is shutting down before the Volumetric Hopper is empty or the machine is not shutting down

when the Hopper runs empty, the Low Level Product Detector could possibly need adjustment. To adjust remove

the black screw from the back of the Detector and inside you will find another screw. By turning this screw

clockwise, the sensitivity will decrease. Keep in mind, the sensor must be installed so the sensor will not read the

Hopper.

Summary of Contents for Hamer 540

Page 2: ......

Page 4: ......

Page 7: ...Rev 4 SECTION ONE MODEL 540 FORM FILL AND SEAL MACHINE...

Page 8: ......

Page 14: ......

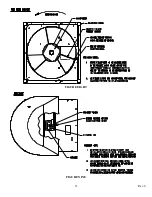

Page 40: ...Rev 4 31 FIGURE EIGHT FIGURE NINE...

Page 47: ......

Page 55: ...Rev 4 45 SECTION TWO MODEL 540 ASSEMBLY DRAWINGS...

Page 56: ......