Rev.4

36

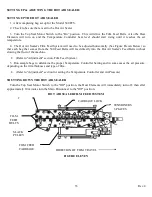

MACHINE SPEED

The operating speed of the Hot Air Sealer may need to be adjusted to match that operating speed of the

Conveyor.

To adjust the speed of the Hot Air Sealer:

•

(Refer to “Touch Screen Display – Operator Control Station” to Adjust the Hot Air Sealer speed as follows:

1. Watch as the product filled bag travels with the Conveyor through the Hot Air Sealer, if the top of the bag is

traveling faster than the bottom of the bag you will need to decrease the speed of the Top Sealer on the Touch

Screen Display – Operator Control Station.

•

(Refer to the Touchscreen, Setup Menu and Top Sealer Speed Control Menu).

2. If the top of the bag is traveling slower than the bottom of the bag you will need to increase the speed of the

Top Sealer on the Touch Screen Display – Operator Control Station.

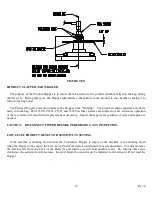

TEMPERATURE CONTROLLER

The proper temperature setting depends on the film thickness and type of film. To set the Temperature

Controller (green led display) uses the up / down arrow buttons. The temperature of the Heat Plenums will rise (red

led display) until it reaches the set temperature and will fluctuate 10 degrees around the set temperature. (See

Figure Two). The recommended starting temperature is 250 F. Increase the temperature until the seal is strong,

then stop. If the seal is to hot the bag breaks under the seal.

•

Note: If you have set the Temperature Controller at a sufficient sealing temperature and the Hot Air Sealer

does not deliver a solid bag seal, increase the air pressure.

•

(Refer to "Air Pressure Regulator / Filter" below).

AIR PRESSURE REGULATOR / FILTER

1. The Air Pressure Regulator should be set at a minimum of 7 PSI, but can be increased to a maximum of 20

PSI. With the Air Supply connected, pull out on the Knob of the Regulator. This unlocks the Knob so that the air

pressure can be adjusted. Once the Gauge reads the required PSI, push the Knob back into the locking position.

WARNING: IF THE AIR PRESSURE FALLS BELOW 3 PSI, THE HEAT ELEMENTS WILL CEASE

TO OPERATE.

2. DO NOT allow the Filter Water Separator Bowl to become full, empty as often as necessary. To empty the

Separator Bowl, push the white tube at the bottom of the bowl to the side and allow it to drain. If water is emptied

frequently every day, an air drier is recommended to increase the heater element, valve, and cylinder life.

Summary of Contents for Hamer 540

Page 2: ......

Page 4: ......

Page 7: ...Rev 4 SECTION ONE MODEL 540 FORM FILL AND SEAL MACHINE...

Page 8: ......

Page 14: ......

Page 40: ...Rev 4 31 FIGURE EIGHT FIGURE NINE...

Page 47: ......

Page 55: ...Rev 4 45 SECTION TWO MODEL 540 ASSEMBLY DRAWINGS...

Page 56: ......