Rev.4

39

TROUBLESHOOTING GUIDE (CONTINUED)

SYMPTOM

CAUSE

CORRECTION

The machine stops and the film is

broken. (the film breaks when the

Dancer Roller is pulled against the

machine frame.)

The Film Unwind Assist

has developed a problem.

The Film Clamp may need adjustment for

clearance or the Cylinder may not be engaging.

Check the Unwind Assist Cylinder for proper

operation of the Dancer Arm. The Film Roll

Holder Brake Cylinder may not be releasing,

not allowing the film roll to unwind. The

Dancer Spring tension may need to be

increased, by moving the Spring Bracket.

The machine stops and the film has

not indexed far enough. The Eye

Mark did not pass the Photo Eye

and no side seal was formed.

The film advanced too

slowly causing the Eye

Mark to time out because

of excess friction between

the Belts and the Fill

Opening.

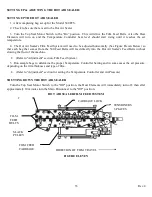

Locate the cause of the friction: Is the water to

the Felt Lubricator functioning properly? Is

the Film Feed Belt pressure too tight? Is the

Film Feed Belt tension tight enough?

In the Auto mode, the machine

stops and the film has indexed too

far without forming a side seal.

The Eye Mark passes the

Photo Eye, but the Photo

Eye did not see it.

Locate the reason that the Photo Eye did not

see the Eye Mark: Does the film have an Eye

Mark printed on it? Is the film threaded

between the Photo Eye and the Reflector? Is

the Eye Mark passing above or below the

Photo Eye Beam rather than through it? Is the

Photo Eye Sensitivity set correctly for the Eye

Mark being used?

In the Auto Mode, the film will not

advance (the volumetric drum is

turning).

Required inputs are not

activating.

Check for inputs from the side seal limit

switch (must open and close with each cycle),

air pressure switch and volumetric drum limit

switch (should open and close when tripped by

the cam).

Volumetric dumps more than once

on the single dump setting (double

dump)

Input from side seal

switch is out of time with

the volumetric Prox

switch.

Sticking or slow clutch air

valve.

Excessive speed of drum

rotation.

Increase the side seal speed with flow control.

Replace the flow control or valve.

Lubricate, clean, or replace the valve.

Reduce the drum speed, maximum soeed is

approx. 40 (dumps) bags per minute.

Volumetric dumps more times than

selected on the four position

switch. The switch is set on two or

more dumps.

Sticking or slow clutch air

valve.

Adjust Prox or

Lubricate, clean, or replace the valve.

Replace Prox.

Volumetric does not dump the

amount selected on the four

position switch.

Adjust Prox or

Replace Prox

Summary of Contents for Hamer 540

Page 2: ......

Page 4: ......

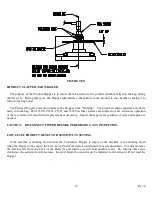

Page 7: ...Rev 4 SECTION ONE MODEL 540 FORM FILL AND SEAL MACHINE...

Page 8: ......

Page 14: ......

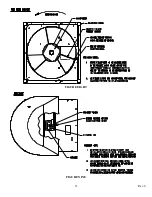

Page 40: ...Rev 4 31 FIGURE EIGHT FIGURE NINE...

Page 47: ......

Page 55: ...Rev 4 45 SECTION TWO MODEL 540 ASSEMBLY DRAWINGS...

Page 56: ......