Rev.4

41

TROUBLESHOOTING GUIDE (CONTINUED)

SYMPTOM

CAUSE

CORRECTION

Bag is tearing under the top

seal.

Seal stress before the seal

cools.

Film is sticking to the

sealing belts (middle belts

on the exit end of the hot

air sealer.)

Sealing temperature is too

high.

Overfilled Bags

Reduce the distance the bags drop when

leaving the hot air sealer. If possible, allow

additional time for the seal to cool before

handling.

Apply release compound (Part # 3430) to the

sealing belts.

Lower the temperature 20

°

at a time until

bags do not seal. Increase the temperature

only to the sealing point.

Decrease the product volume or increase the

bag size. Reduce the volume as a test first.

Lower the bag conveyor and film height

above the feed belts.

Bags have poor or no top seal.

The two sheets of film are not

welding together.

Temperature is not high

enough.

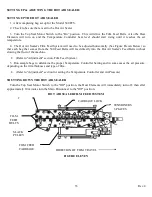

Inadequate air flow

Excessive amounts of

water padding thru the hot

air plenums.

Inadequate pressure

between the belts.

Speed is mismatched

between the top V belts

and the bag conveyor belts.

Increase the set point on the temperature

control 20° at a time until the bag seals, or

the bag melts down in sections of the bag

top. If the bag top is melting off before the

bag leaves the sealer, reduce the temperature

and look at other causes.

Increase air pressure to the hot air plenums

(average pressure is 7-15 psi). Clean plenum

air holes (the holes are .040 in diameter).

Disassemble and clean the plenum.

Drain the water from the filter(s) and

consider installing an air drier.

Increase the pressure between the belts.

Depending on your machine model, this may

be a mechanical or air pressure adjustment.

Adjust individual pulleys to be in a straight

line were applicable (plate style sealers).

Adjust the trim block (if used) to be in a

straight line with the V belt pulleys. Replace

the belts and or worn pulleys.

The top V belts have a speed adjustment.

Adjust the speed so the top of the bag is

traveling the same speed as the bottom. The

bag top should not lean left or right.

Summary of Contents for Hamer 540

Page 2: ......

Page 4: ......

Page 7: ...Rev 4 SECTION ONE MODEL 540 FORM FILL AND SEAL MACHINE...

Page 8: ......

Page 14: ......

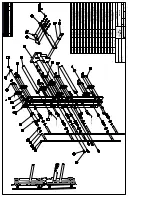

Page 40: ...Rev 4 31 FIGURE EIGHT FIGURE NINE...

Page 47: ......

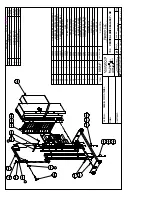

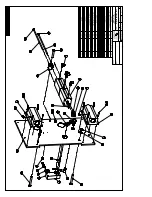

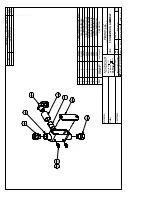

Page 55: ...Rev 4 45 SECTION TWO MODEL 540 ASSEMBLY DRAWINGS...

Page 56: ......