Rev.4

43

TROUBLESHOOTING GUIDE (CONTINUED)

SYMPTOM

CAUSE

CORRECTION

The side seals are weak. The

side seals are open or tear

apart easily – (Continued).

Slight film movement while

the side seal is being made.

Low air pressure

Excessive wrinkles in the

film at the seal bar.

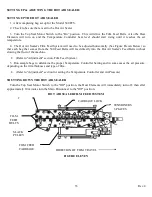

Adjust the film clamp to hold securely.

Rebuild or replace the fill opening cylinders if

operating slow or at unequal speed. Replace

both top “V’ Belts if one or both are worn.

The belts may be running at uequal speeds.

Check all the belt path pulleys and bearings for

damage and wear. Check the pressure between

the V pulleys, particularly the two just before

the fill opening. They should apply equal

pressure. Adjust and / or replace the orange

runner clamp tubes. Check the brake for

proper operation. Clean or replace the air

valve or brake. Adjust the jaws inline with the

film opening rod.

Machine air pressure should be set at a

minimum of 80 PSI. Check for leaking air

cylinders on vertical sealer, replace as needed.

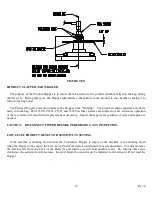

Check the film opening rod. This rod should be

centered under the belt path. The rod should

have a 3/16” spacing below the belts. Check

the alignment of the seal pad and belt path

centerline. The seal pad should not protrude

beyond the centerline. Level and plumb the

film roll platter.

Summary of Contents for Hamer 540

Page 2: ......

Page 4: ......

Page 7: ...Rev 4 SECTION ONE MODEL 540 FORM FILL AND SEAL MACHINE...

Page 8: ......

Page 14: ......

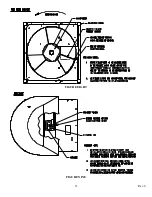

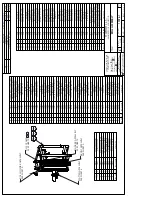

Page 40: ...Rev 4 31 FIGURE EIGHT FIGURE NINE...

Page 47: ......

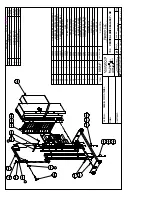

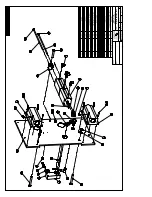

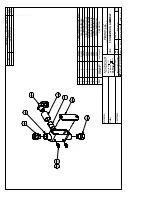

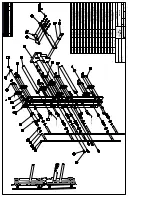

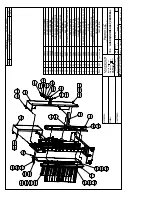

Page 55: ...Rev 4 45 SECTION TWO MODEL 540 ASSEMBLY DRAWINGS...

Page 56: ......