P a g e

|

50

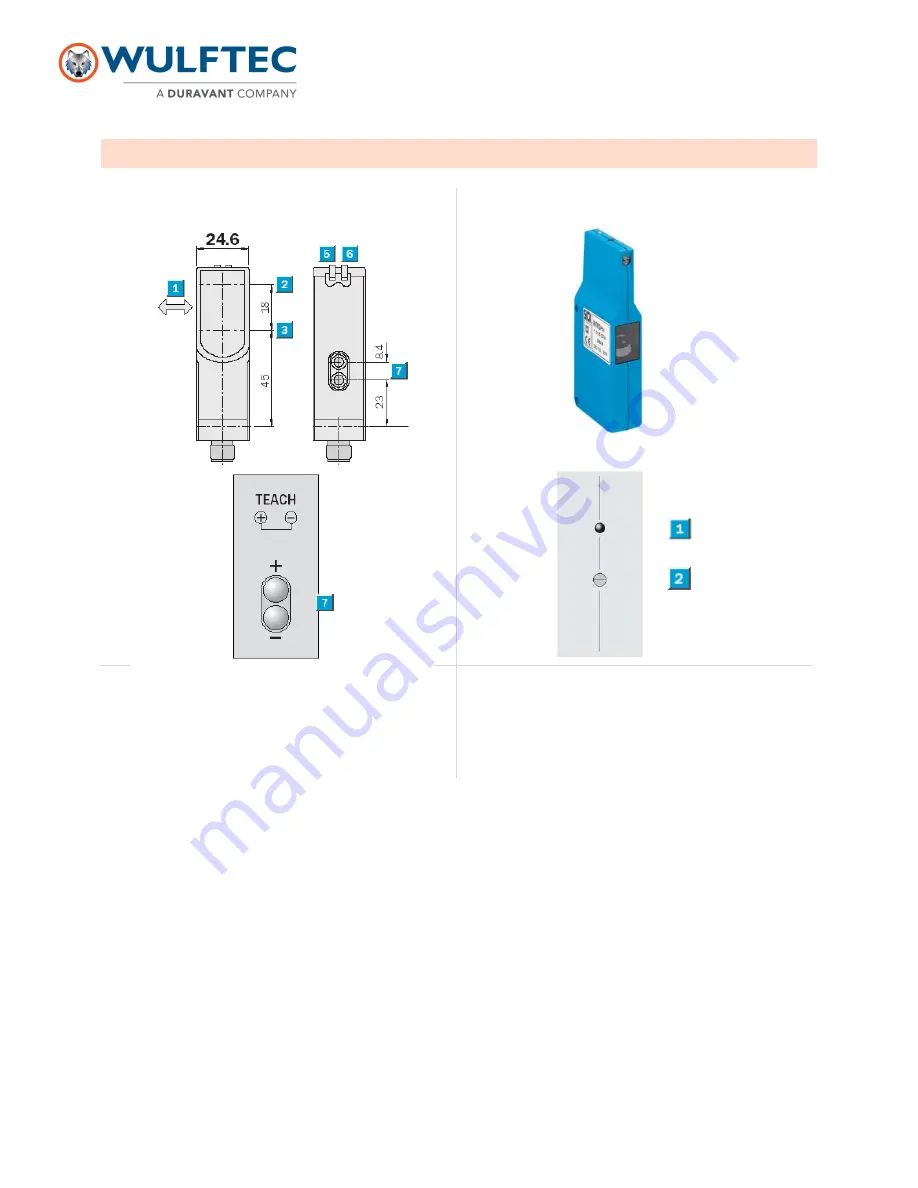

PHOTOEYE ADJUSTMENT (DIFFUSE)

1.

Standard direction of the material being scanned

2.

Optical axis sender

3.

Optical axis receiver

4.

Mounting hole Ø 5.2mm

5.

LED indicator green: power on

6.

LED indicator yellow: status of received light beam

7.

Adjustment of scanning distance: double teach button

1.

LED signal strength indicator

2.

Sensing range adjustment

Diffuse Photoeye (standard and conveyor)

LED Indicators:

Each sensor features two LED indicators to help you program and use the sensor.

Green:

The green LED indicates “power”. When this indicator is lit, power is on.

Amber (Yellow):

The amber or yellow LED indicates “status.” This indicator will light up when an output signal is

activated.

Sensitivity adjustment on std diffuse PE:

To adjust sensitivity, place a load at the middle of the turn table or at the

center of the axis of rotation then press & hold both button (+) & (-) until the led flashes. If you want to fine tune the

sensitivity you can press (+) OR (-) until you read the load at the desired distance.

Adjustments on conveyor diffuse PE:

To adjust, place a cardboard box about ¾ of the conveyor (on the side

farthest from the PE. Adjust sensitivity from there.