P a g e

|

75

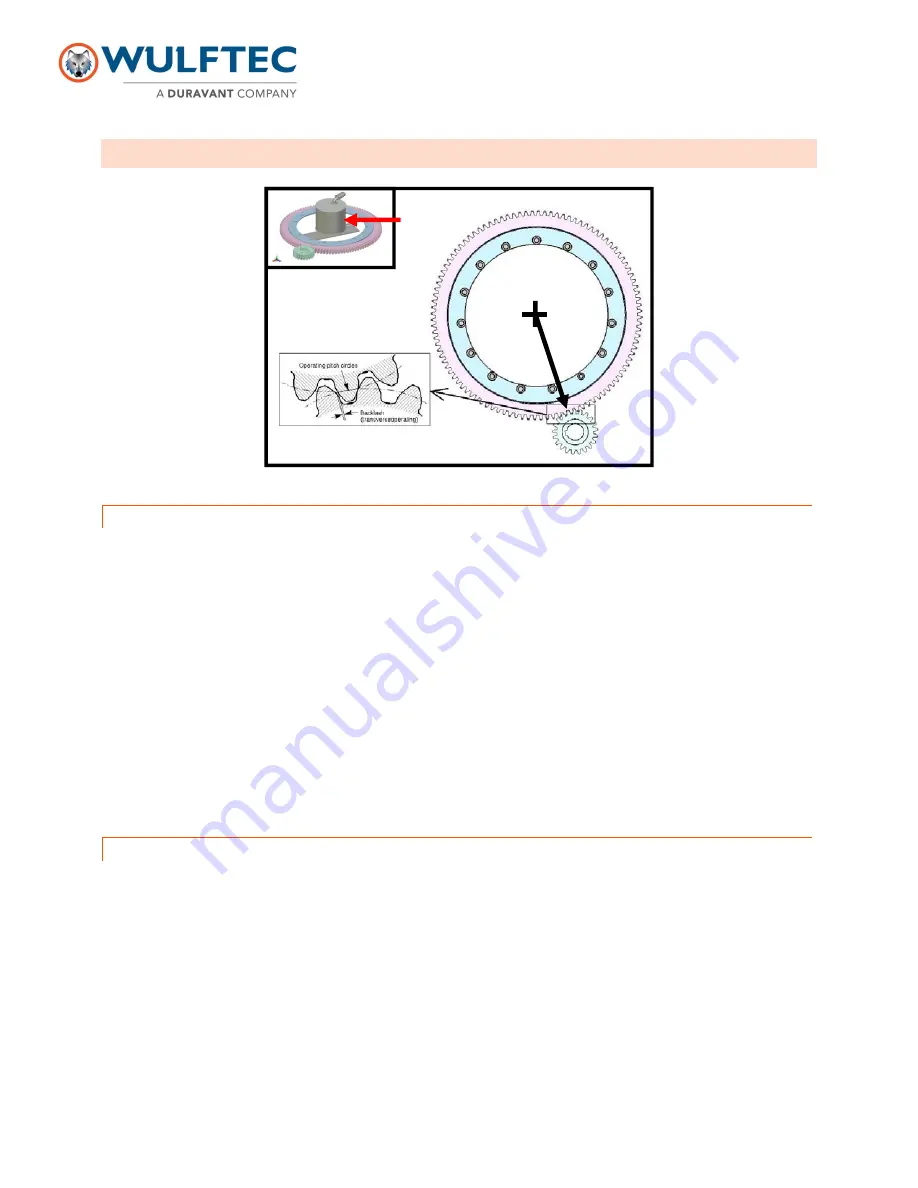

RING GEAR

PINION-RING GEAR

Remove the ring gear cover and wipe the accumulated grease. Measure the backlash between the pinion and ring

gear, it should not exceed 0.010in and nominally, the backlash should be at 0.005 in. Beware that a ring gear is not

perfectly round. There are some markings on the outer race indicating furthest point from the center. Always verify

the backlash when these markings are aligned with the pinion. Backlash verification should be done every 2,800

hours. A retightening of the screws is required after 100 hours of operation and should be subsequently checked

every 3 months.

Teeth

Visually inspect the teeth once a month after inspecting the run systems (correct lateral tooth play). Remove buildup if

present. With steel pinion, if teeth are dry, apply grease with a brush all around ring gear. Use high quality open

gear grease (Mobile Unirex EP2 GCLB or equivalent). With nylon pinion, no greasing is necessary.

Slip ring

Conductive powder accumulates in the canister and it is strongly recommended to blow the assembly with

compressed air every 2,800 hours of machine operation.

BEARING

Lubrication of the bearing component is provided through the auto-lube system. The automatic lubrication station

only greases the ring gear bearing. For any other component that needs greasing, do a visual inspection every month

and add grease as needed. Operation of the auto-lube is detailed under. Make sure the auto-lube does not go out of

lubricant.

For machines without the auto-lube system, apply EP2 grease with a grease pump every 100 hours of operation, or

as part of your regular maintenance program (in more humid conditions, strong temperature variations and constant

rotation, regreasing should be repeated in shorter time intervals). Move bearing several times to ensure complete fill.

You may use appropriate grease if you have requested a different type of grease in your system (ex. FDA-approved)

or if your operating environment requires a different type of grease (ex. cold temperature environment).

Inspect the seals to ensure they are properly inserted into their grooves and that they are intact and preventing

contaminants from entering the bearing

Slip ring