12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

3

5

5.5

7.5

7

9

6.5

8.5

8

10

4

6

Nominal Pipe

Size (inches)

Min. Hole

Size (inches)

Max. Hole

Size (inches)

QUICK GRIP - FIRESTOP/SUPPORT

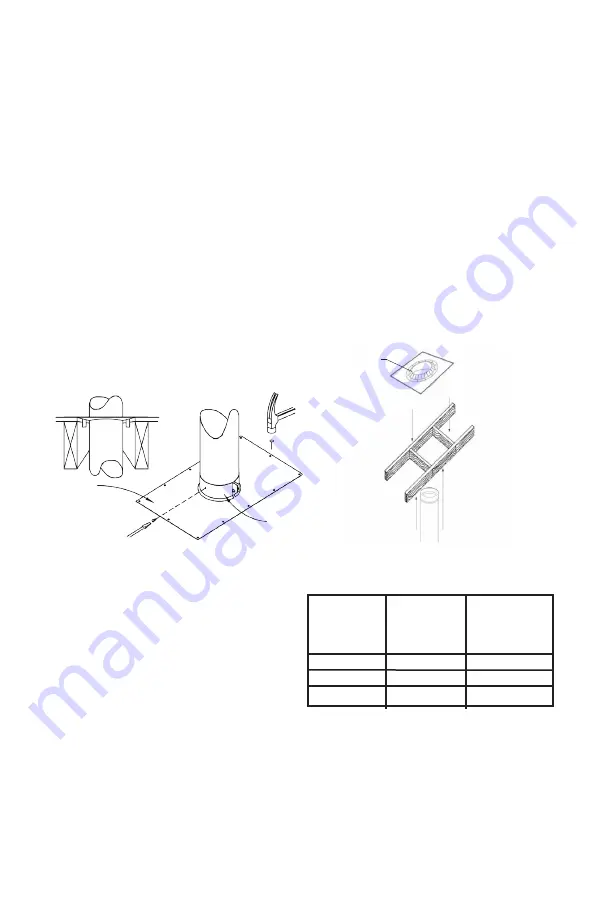

1. At the desired location, cut a square

or circular hole in the floor at a minimum

of 2-1/2 inches larger than the nominal ie

size, but not greater than 4 inches larger.

See the table below. This will provide the

REQUIRED 1-INCH CLEARANCE FROM

COMBUSTIBLES.

2 Place the support over the hole with the

gripping fingers up (see Fig. 13).

3. Use an 8 penny nail or self-drilling sheet

metal screw in each corner at least 3/8 of an

inch in from the edge.

4. Pipe should be inserted from below. A

maximum of 30 feet of pipe may be installed

above the suport before resupport is required.

FIG. 13 - “Quick Grip” Firestop/Support

Clamping

Band

FIG. 12 - Firestop/Support Plate Assembly

Insert the first length from above through

the clamp band and opening of the support

plate to proper elevation. Secure clamping

band to the length with tabs and 1/4” screws

(provided) so weight of vent rests on plate.

Room should be left for the draft hood

connector and adjustable length.

Vertical runs fire stopped at 8 to 10 foot

intervals need only be supported near the

bottom. Additional Gas Vent Lengths above

the Support are simply stacked on. See

joining section to secure lengths together.

12. SUPPORT - PRIMARY AND OFFSETS

- 3” TO 8”

Gas vent piping must be securely supported.

Lateral runs are to be supported at least every

5 feet. The Support Plate has been tested

to support a maximum of 35’ of Gas Vent;

if additional height is required, use another

Support Plate on another floor level. It is

permissible to use the clamping band with a

generic 26 gauge or heavier plate (if space

requirements dictate).

Cut away and frame a four sided opening in

the floor from which the Gas Vent shall be

supported, to provide 1” (25mm) minimum

clearance to combustibles. See Fig. 12.

Nail Support Plate securely to joist and

framing members using 4 x 1-1/2” long nails

(1 nail at each corner).

Support Plate

may be trimmed or

replaced with custom size,

generic plate if

necessary, as long as

the required clearances

are respected

Tees used as vent inlets may be supported

by sheet metal plates or brackets. Plumbers

tape may be used to support both horizontal

and vertical piping. Short vents with less than

6 feet of vertical pipe below the flashing may

be suspended from the flashing. (The pipe

may be supported by the storm collar resting

on the top of the flashing). Use 1/4 inch

long sheet metal screws to attach the storm

Gripping

fingers

facing

upward