1

INSTALLATION

INSTRUCTIONS

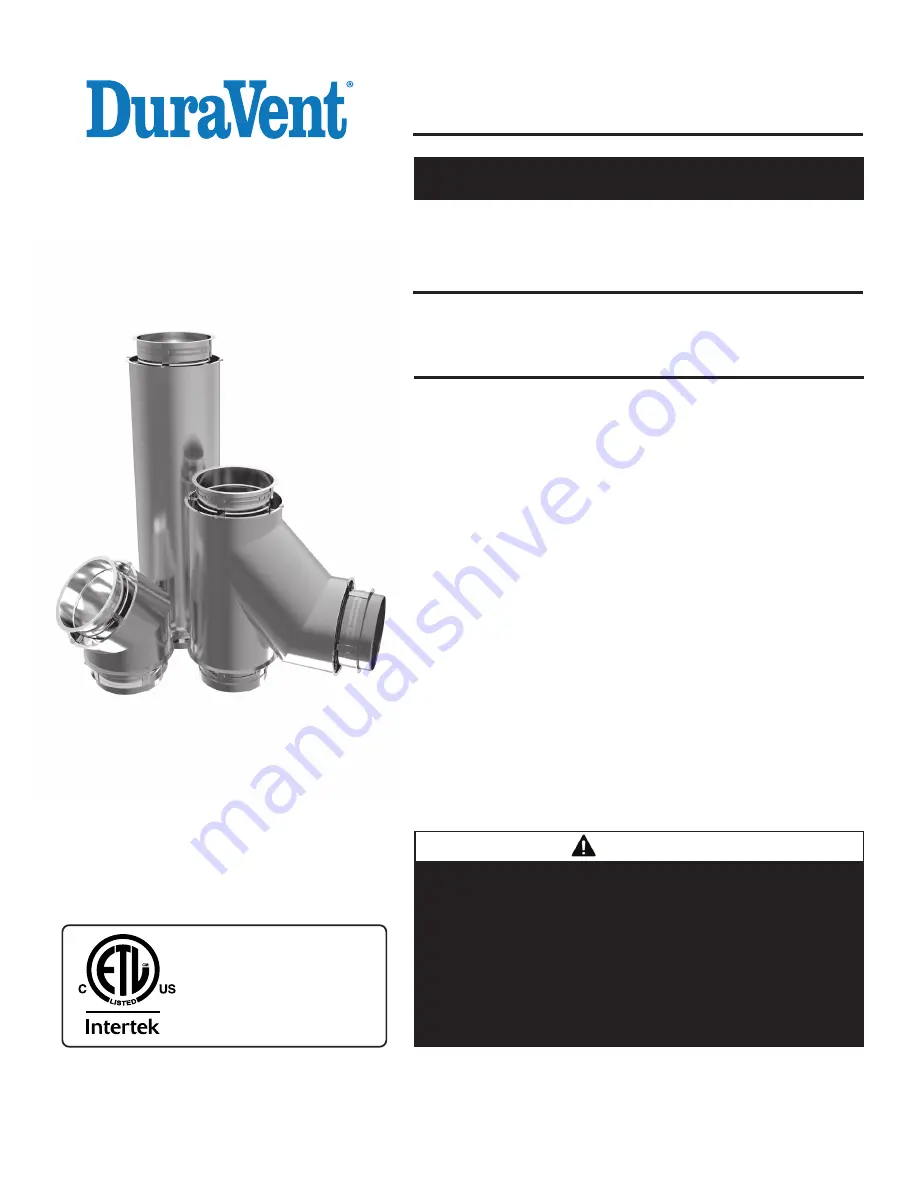

1" air Double Wall for Special Gas Vent

Category I, II, III, and IV Applications.

5” to 36” Diameter Vent for use on Positive, Neutral and Negative Pressures

up to 35” W.C.

This installation manual will enable you to obtain a safe, efficient and dependable

installation of this vent system. Please read and understand these instructions

before beginning your installation.

Do not alter or modify the components of this chimney system under any circum-

stances. Any modification of alteration of the vent system or approved accesso-

ries, including but not limited to the appliance it is connected to, may void the

warranty, listings and approvals of this system and could result in an unsafe and

potentially dangerous installation.

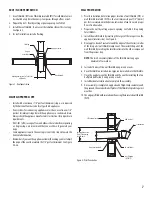

A. Examine all components for possible shipping damage prior to installation.

B. Proper joint assembly is essential for a safe installation. Follow these

instructions exactly as written: Check severeness of joints upon completion of

assembly.

C. This venting system must be free to expand and contract. This venting system

must be supported in accordance with these instructions.

D. Check for unrestricted vent movement through walls, ceilings, and roof

penetrations.

E. Different manufacturers have different joint systems and adhesives. Do not mix

pipe, fittings, or joining methods from different manufacturers.

WARNINGS

FAILURE TO FOLLOW THESE INSTALLATION INSTRUCTIONS COULD CAUSE FIRE,

CARBON MONOXIDE POISONING, OR DEATH. IF YOU ARE UNSURE OF INSTALLA-

TION REQUIREMENTS, CALL THE PHONE NUMBER LISTED ON THE BACK OF THESE

INSTRUCTIONS.

A MAJOR CAUSE OF CHIMNEY RELATED FIRE IS FAILURE TO MAINTAIN REQUIRED

CLEARANCES (AIR SPACES) TO COMBUSTIBLE MATERIALS. IT IS OF UTMOST IM-

PORTANCE THAT THIS VENT SYSTEM BE INSTALLED ONLY IN ACCORDANCE WITH

THESE INSTRUCTIONS

PI HYBRIDDAS1 L470 REV. 00 08-08-19

Listed to standards:

UL-1738

ULC-S636 Type ‘‘BH’’ vent

Report #

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

MODEL DAS1-(BC) (5" TO 36")