13

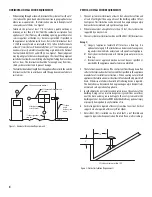

Flange to flange length adjustment can range from 7”x 281/2”

NOTE:

If the flue is too long to fit into the adjacent section of duct without

interfering with the flow path, it should be trimmed to desired flange

to flange length plus an overlap of 4” with the inner wall of the inlet

end duct section. The minimum overlap for the outer casing is 1” with

the inlet end section outer wall. (See Figure 12 & 14).

NOTE:

If an LV joint must be joined to one of these fittings, the unflanged

end of the tube should always point downward or towards downward

slope.

Figure 12 - Overlap Details for Variable Length

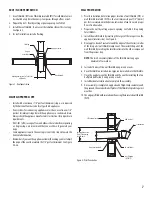

INSTALLATION STEPS FOR THE VARIABLE LENGTH (LV)

Step 1

- Measure the distance X required for the variable length. See

Figure 13.

Figure 13-Step 1 for Installation of Variable length

Step 2

- Cut the inner wall at the dimension X found at the first Step plus

4”. See Figure 14.

Step 3

- Cut the split outer casing on the opposite side of the flanged half

at dimension X plus 1’’. See Figure 15.

Figure 14 -Step 2 -

Cut of the Sliding Inner Wall

Figure 15 - Step 3 -

Cut of the Outer Casing

Cut Split Outer

casing to X + 1”

Cut Sliding Inner

Wall to X + 4”

Distance ”X”