6

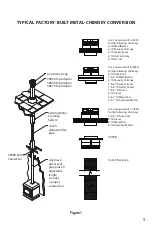

Figure 3

chimney, a Top Adapter (985K) and Flashing

are used at the top of the masonry chimney.

The 4-inch aluminum liner is connected to

the adapter and is passed down the chimney

and out through the masonry wall. This

is attached to the Retro Connector (909B)

which is in turn, attached to the masonry wall

and is then connected to the direct vent pipe

leading to the appliance.

INSTALLATION INSTRUCTIONS

FOR CONVERTING A FACTORY

BUILT METAL CHIMNEY

Step 1. Remove the existing chimney cap.

Step 2. Measure the distance from the top

end of the chimney to the bottom of the

ceiling support box, add 3 inches to this

measurement, and cut a section of 4-inch flex

pipe to that length (the flex should already be

extended to its nominal length).

Step 3. Connect the end of the flex pipe

section to the underside of the Top Adapter

you have selected, using (3) sheet metal

screws. (Figure 2.)

Step 4. Pass the flex pipe down through the

center of the chimney system, and center

the adapter on the top of the chimney pipe.

Drill (4) 1/8-inch diameter holes through the

adapter, and into the chimney top. Insure

that you are in fact, drilling into the metal on

the chimney. Twist-lock the Termination Cap

(980 or 991) onto the Adapter. (Figures 3 and

4.)

Step 5. Pull the flex pipe down through

the ceiling support box, until it protrudes

approximately 3 inches. Connect the flex

pipe to the Retro Connector by slipping it

into the 4-3/4-inch diameter sleeve on the

top side of the Connector. Use (3) Sheet

Metal Screws, to assemble these two parts.

Figure 2

Top Adapter

Flex Pipe

Sheet Metal

Screws

Summary of Contents for DirectVent Pro

Page 11: ......