26

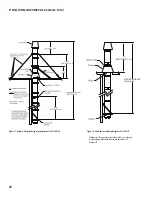

OFFSETS (DSLS-DSLD)

1. The length of the offset is determined by strength considerations. The

maximum dimension between supports is given in

Table 7 & 8

, and is

applicable to all horizontal and sloped orientations. See

Figure 44.

2. The minimum offset is accomplished with two elbows dircectly

connected to each other (see

Figure 43 and Table 15 & 16)

.

3. With frequent re-support, there is no structural or operating limit to the

length of horizontal or sloped portions, providing the system meets

the capacity, pressure drop of available equipment.

4. The carrying capacity of supports and their structural attachments must

take into account the weight of the offset plus whatever vertical section

is carried by that support.

5. Height limits for supports are tabulated in

Table 6

.

6. The vertical sections above the offset must also be supported or

anchored and guided where necessary.

7. Anchor Plate Wall Support (WSHD) and Wall Guide (WGHD) may be

used in a varitey of ways for offset support to achieve the structural

stability of the system.

8. Re-supports must be securely anchoredtowalls, posts, or locally

fabricated rigid framework. This framework must be designed to assure

stability of supports, such as Ventilated anchor Plate (APV) supports and

Heavy Duty Wall Supports (WSHD).

9. Supports suspended by threaded rods or from small size angles or straps

are usually not satisfactory to resist bending moments due to offsets

Figure 44: Maximum Spacing

between supports for Offset

ADAPTERS (DSLS-DSLD)

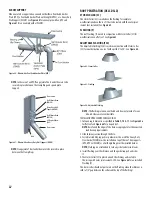

TAPERED INCREASER (TIN0)

The Tapered Increaser Adapter is used for a diameter change in duct

system. Uses when there is a sufficient length for duct run available for the

size change. The TIN0 is used uses 2” of length per 1 “increment diameter

change. The TIN0 is considered to have the same load strength as a

straight duct. See

Figure 45.

Figure 45: Tapered Increaser Adapter (TIN0)

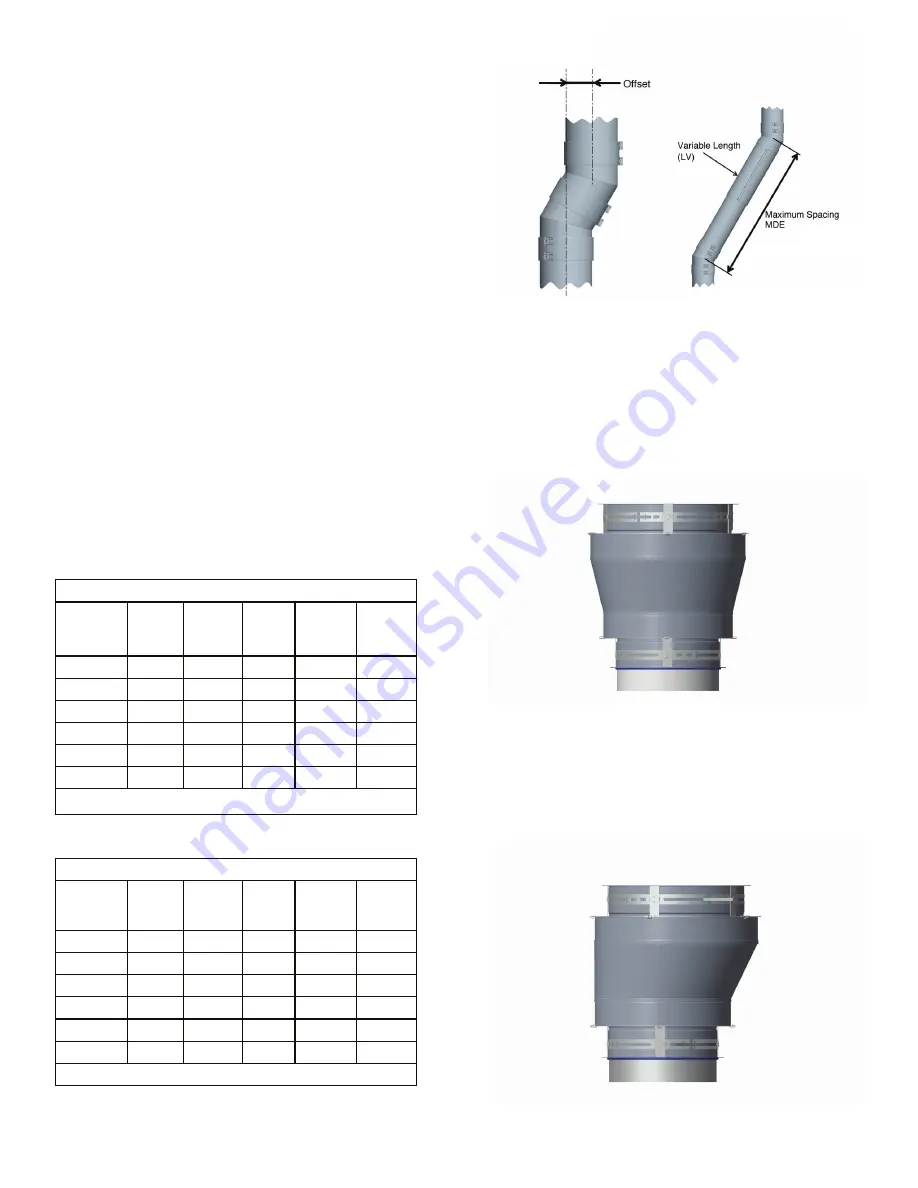

ECCENTRIC TAPERED INCREASER (ETIN0)

The Eccentric Tapered Increaser Adapter is similar as the Tapered Increaser

Adapter except the smaller diameter is offset from the larger diameter.

When installed horizontally, the ETIN0 keep a flat slope unlike the TIN0.

See

Figure 46.

Figure 46: Eccentric Tapered Increaser (ETIN0)

Figure 43: Minimum Offset for each Elbows

DSLS

Flue Diameter

Ø (in.)

3°

15°

30°

45°

90°

26

3/8

2 5/8

6 7/8

12 7/16

34 1/4

28

3/8

2 11/16

7 1/8

13

36 1/4

30

3/8

2 3/4

7 3/8

13 9/16

38 1/4

32

3/8

2 7/8

7 5/8

14 1/8

40 1/4

34

3/8

2 15/16

7 15/16

14 3/4

42 1/4

36

3/8

3

8 3/16

15 5/16

44 1/4

TABLE 15 - Minimum Offset for Each Elbow - DSLS

Dimensions are in inches

DSLD

Flue Diameter

Ø (in.)

3°

15°

30°

45°

90°

26

1/2

3 1/4

8 1/8

14 3/8

39 1/2

28

1/2

3 1/4

8 3/8

14 7/8

41 1/2

30

1/2

3 3/8

8 5/8

15 1/2

43 1/2

32

1/2

3 3/8

8 7/8

16 1/8

45 1/2

34

1/2

3 1/2

9 1/8

16 3/4

47 1/2

36

1/2

3 1/2

9 1/2

17 1/4

49 1/2

TABLE 16- Minimum Offset for Each Elbow - DSLD

Dimensions are in inches

Table 7 & 8