7

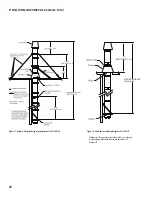

Figure 2- Vertical Installation Requirements

MAINTAIN PROPER SLOPE

• Install with a continuous 1/4” per foot (minimum) slope, as is required

by the National Fuel Gas Code for all gas-fired appliances.

• Vent systems for condensing appliances must have a continuous 1/4”

per foot (minimum) slope toward the appliance or a condensate drain.

Always check the appliance manufacturer’s instructions for proper drain

requirements.

• DuraSeal® offers a range of tees and elbows that are built incorporating

a 2 degree slope, we recommend that you use these to generate your

slope.

• Some appliances require the venting system to be sloped toward the

horizontal termination.

• Remember, if you raise the appliance or lower the ceiling you must adjust

the slope of the vent to maintain the 1/4” per foot minimum. See

Figure

5 & 26.

VERTICAL INSTALLATION REQUIREMENTS

1. The vent system must terminate at least 3 feet above the roof line and

at least 2 feet higher than any portion of the building within 10 feet.

See

Figure 2.

This limitation can be removed if an engineering analysis

demonstrates normal and safe operation of appliance.

2. When terminated at a height of more than 10 feet, the stack must be

supported by a Guy Section.

3. The vent system must terminate with one of the DuraSeal® terminations.

Except;

a) Category I appliances (natural draft) must use a Rain Cap. It is optional

on Category II. This limitation can be removed if an engineering

analysis demonstrates normal and safe operation of appliance.

b) Vent systems without provisions for draining rain water must use a

Rain Cap.

c) Terminations or approved mechanical vent devices specified or

provided by the appliance manufacturer are permitted.

4. The total continuous distance of the vent system from the appliance flue

collar to the termination shall not exceed that specified in the appliance

manufacturer’s installation instructions. When venting natural draft ap-

pliances the termination must be at least 5 feet above the topmost draft

hood. Otherwise a listed mechanical draft inducing device is required.

This limitation can be removed if an engineering analysis demonstrates

normal and safe operation of appliance.

5. In general, systems installed in cold climates perform best, and condensa-

tion is reduced, when the system is fully enclosed by some part of the

building structure or by using insulated DSID venting system.

6. In cold climates do not install a condensate drain on the exterior of the

building. Doing so may result in dangerous icy conditions on surfaces

near the drain and may cause damage to the vent system and/or the

building exterior. DuraVent will NOT be held liable for any personal injury

or property damage due to any formation of ice.

7. Vertical supports are required after every transition to vertical. Vertical

supports are also required after every offset elbow.

8. Unless DuraSeal is installed in a fire rated shaft, a roof thimble and support

is required when penetration fire rated floors, walls or ceilings.

2 ft. above structures within 10 ft.

10’

2’

ROOF / FLOOR PENETRATION

1. A roof thimble (RT) or roof thimble insulated (RTI) for cold climate must

be installed every time the vent system passes through a floor or roof.

2. Prepare the roof / floor by cutting a square opening. See

Table 9, 10 &

11.

3. Install the roof thimble. You may cut the radiation sleeve if it is too long.

See

Figure 3

.

4. For roof installation, install a flashing.

Support or Guide

Roof thimble

Opening dimension See Table 9,

10 & 11 for all Models

Air gap

or insulated

Flashing

Figure 3 - Roof penetration