10

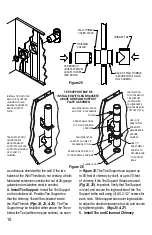

8. Install Attic Insulation Shield:

The

Attic Insulation Shield is required where the

chimney passes into an attic. Its purpose is

to prevent debris and insulation from getting

too close to the chimney

(Fig 10)

. An installed

Attic Insulation Shield is 15 inches high. In

attic areas where this shield cannot fit, you

must enclose the attic portion of the chimney

in a framed enclosure. If the chimney is fully

enclosed through the attic, an Attic Insulation

Shield is not required. If the chimney passes

into the attic, install the Attic Insulation Shield

as follows:

a.

If the Firestop Radiation Shield extends

above the attic floor, no modifications are

necessary. The Firestop Radiation Shield will

fit inside the Attic Insulation Shield.

b.

Assemble Chimney Sections until at least

18 inches of chimney extends above the

Firestop Radiation Shield.

c. Extend the Firestop Radiation Shield tube

extension (keep at least 1” overlap), and

secure in place using sheet metal screws.

d. Slip the Attic Insulation Shield over the

Chimney and Firestop Radiation Shield until

the base sits squarely on the framed opening

(Fig 7 & 10)

.

e. Secure the Attic Insulation Shield to the

top of the framed opening using at least (3)

8-penny nails or (3) #8, 1-1/2” wood screws

per side

(Fig 10)

.

f.

Wrap the Collar of the Attic Insulation Shield

around the chimney and fasten it loosely. Slide

the Collar down to meet the Attic Insulation

Shield. Slip the tab through the adjacent slot

and fold it back to tighten and secure the

Collar

(Fig 11)

.

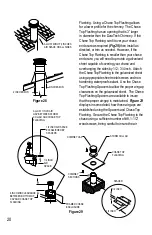

9. Attach Flashing:

In new construction,

assemble the Chimney Sections to a point

above the roof, then slip the Flashing over

the chimney. On an existing roof, center

and install the Flashing before extending the

Figure 11

Figure 12

Figure 13

ROOFING

FASTENERS

ADJUSTABLE

FLASHING

PUSH COLLAR

DOWN TO

FLASHING AND

SEAL WITH NON-

HARDENING HIGH-

TEMP SILICONE

SEALANT

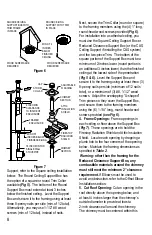

7. Assemble Chimney Sections:

Lower

the female end of the first Chimney Section

in the Support Box

(Fig 9)

. It will twist-lock

clockwise onto the male end of the Support

Box. Turn Pipe Sections firmly clockwise to

lock them together. Sheet metal screws are

not required, but they may be used to reinforce

the connection, if desired. Use only 1/2” (or

shorter) sheet metal screws. Do not penetrate

the inner liner of the chimney.