12

2 pairs of Elbows in any one chimney system.

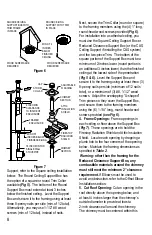

1. Attach Elbows:

Attach Elbow to Chimney

Section or other Elbow by twisting clockwise

until they lock firmly. Attach one Elbow to the

Chimney Section below, and align it for the

offset. Elbows for DuraTech have a swivel

feature that allow for 360º rotation at their base

for ease of installation. Refer to

Table 3

to

determine the required offset length and attach

an appropriate length (or lengths) of Chimney

Section(s) above the Elbow.

Important:

For each chimney pipe section in the offset

(between the elbows), there must be an Elbow

Figure 15

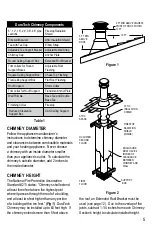

Table 3

Elbow

Angle

from

Vertical

Chimney

Length

Between

Elbows

Offset

Inches

Rise

Inches

15”

0”

2”

16 ½”

15”

6”

3 ¼”

21 ¼”

15”

12”

4 ¾”

27

15”

18”

6 ¼”

32 ¾”

15”

24”

8”

38 ½”

15”

36”

11”

50 ¼”

15”

48”

14 ¼”

61 ¾”

15”

48” + 6”

15 ½”

66 ½”

15”

48” + 12”

17”

72 ¼”

15”

48” + 18”

18 ½”

78:

15”

48” + 24”

20”

83 ¾”

30”

0”

4”

15 ¾”

30”

6”

6 ¼”

30”

12”

9 ¼”

25 ¼”

30”

18”

12 ¼”

30 ¼”

30”

24”

15 ¼”

35 ½”

30”

36”

21 ¼”

46”

30”

48”

27 ¼”

56 ¼”

30”

48” + 6”

29 ¾”

60 ½”

30”

48” + 12”

32 ¾”

65 ¾”

30”

48” + 18”

35 ¾”

71”

30”

48” + 24”

38 ¾”

76”

Strap, Tee Support, or similar support method

to support the weight of the pipe and to relieve

stress on the Elbows. Attach the second Elbow

above the Chimney Section to complete the

offset

(Fig 15)

.

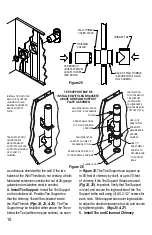

2. Secure Offset:

Place the Elbow Strap’s

band around the angled portion of the top

Elbow, then tighten the nut and bolt until the

clamp is firm. Wrap the Elbow Strap end over

an adjacent joist or rafter and secure it with at

ELBOW STRAP

ELBOW

ELBOW

ELBOW STRAP

ADDITIONAL ELBOW

STRAPS REQUIRED

FOR EACH CHIMNEY

SECTION USED IN

OFFSET

RISE

(INCHES)

CHIMNEY

SECTION

OFFSET

(INCHES)

ELBOW STRAPS

OR TEE SUPPORTS

ARE REQUIRED TO

SUPPORT WEIGHT

OF OFFSET AND

TO RELIEVE

STRESS ON

ELBOWS

TWO OR MORE

CHIMNEY

SECTIONS