Operation

18

Operating Instructions 512/532 - 05.0 - 04/2018

With the correct setting the needle thread loop must slide over the

thickest part of the hook at low tension.

To set the needle thread regulator:

1.

Loosen the screw (3).

2.

Adjust the position of the thread regulator (1).

Thread regulator to the left = larger amount of needle thread

Thread regulator to the right = smaller amount of needle thread

3.

Tighten the screw (3).

Adjustment note:

When the maximum thread quantity is required then the thread

tension spring (2) must be pulled approx. 0.5 mm down from its

upper end position. This occurs when the needle thread loop

passes the maximum hook diameter.

3.4

Winding the hook thread

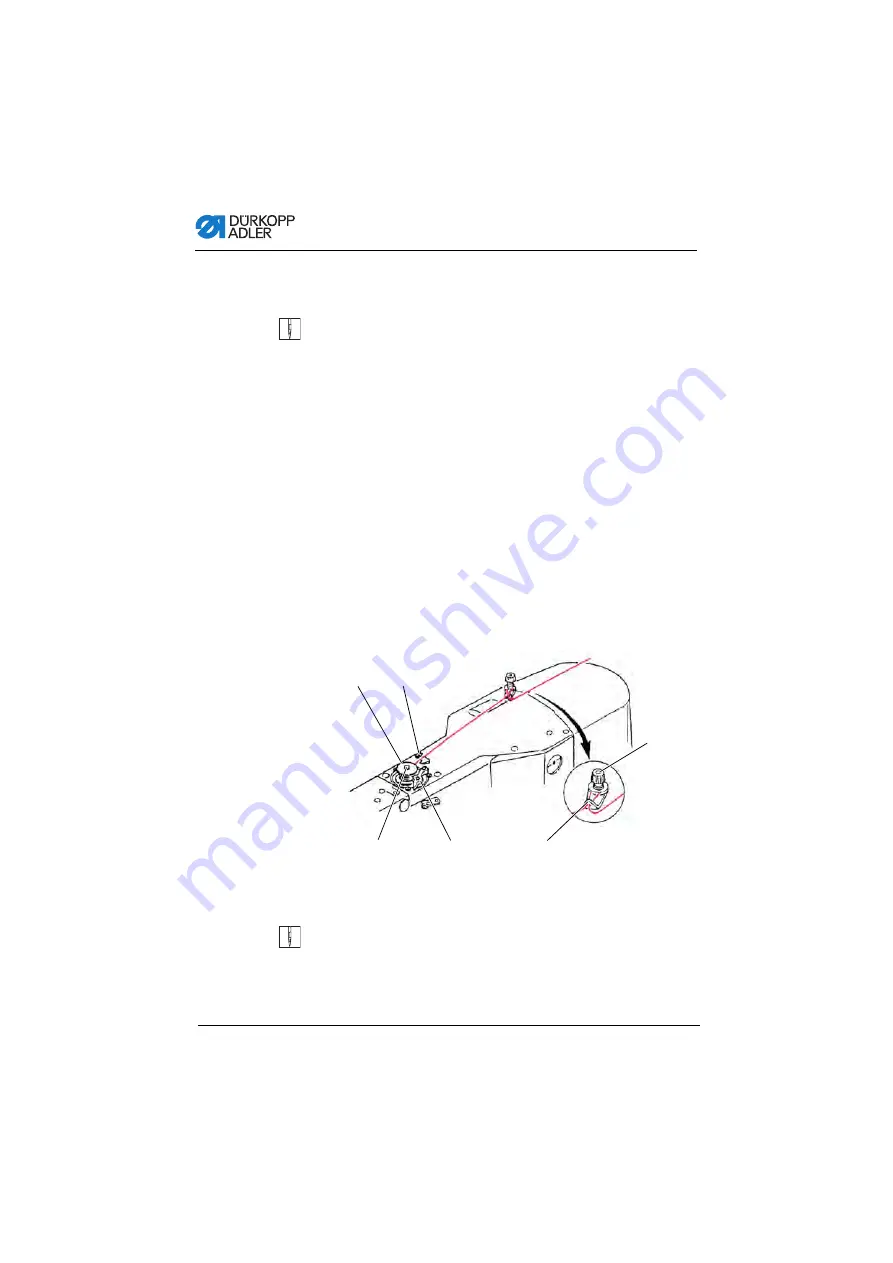

Fig. 4: Winding the hook thread

To wind the hook thread:

1.

Fit the bobbin (2) on the bobbin shaft (3).

2.

Pull the thread through the guide (5) and around the

tensioner (6).

(1) - Thread clamp

(2) - Bobbin

(3) - Winder shaft

(4) - Bobbin lever

(5) - Guide

(6) - Tensioner

③

④

⑤

①

②

⑥

Summary of Contents for 512/532

Page 1: ...Operating Instructions 512 532 ...

Page 6: ...Table of Contents 4 Operating Instructions 512 532 05 0 04 2018 ...

Page 16: ...Safety 14 Operating Instructions 512 532 05 0 04 2018 ...

Page 60: ...Programming 58 Operating Instructions 512 532 05 0 04 2018 ...

Page 70: ...Maintenance 68 Operating Instructions 512 532 05 0 04 2018 ...

Page 86: ...Decommissioning 84 Operating Instructions 512 532 05 0 04 2018 ...

Page 88: ...Disposal 86 Operating Instructions 512 532 05 0 04 2018 ...

Page 97: ...Appendix Operating Instructions 512 532 05 0 04 2018 95 11 Appendix ...

Page 98: ...Appendix 96 Operating Instructions 512 532 05 0 04 2018 ...

Page 99: ......