General information

6

Additional Instructions 911 - 00.0 - 05/2020

Information

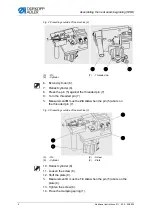

The old throat plate holder and the old throat plate must be replaced by

the new throat plate holder and the new throat plate included in the kit.

9731 005004

1

Hose PUR, gray (2.5 m)

0911 200404

1

Throat plate holder

0911 200250

1

Throat plate

Part number

Quantity

Description