Form stitch mechanism of machine 525

Service Instructions 52Xi, 52Xi-75 - 00.0 - 11/2021

29

5.2

Roller bolt position of form stitch steering cam

Proper setting

When changing the form stitch width, the stitch central axis should remain

in its place. It should not shift laterally.

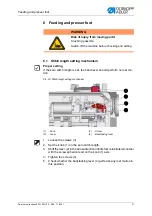

Pic. 18: Roller bolt position of form stitch steering cam

1.

Mount the wheel steering cam of the straight stitch (from the machine

rear side).

2.

Dismantle the cover of the form stitch width setting mechanism.

3.

Release the bolt (2) position by tilting the lever (1) in yourself direction.

4.

Move the bolt (2) in the arrow direction and watch whether the needle

is moving laterally. If yes, dismantle the steering cam, loosen the

screw (3) and try to turn the eccentric bolt (4) to a different position and

test whether the needle is changing its position. Repeat this until the

eccentric bolt (4) position is found where the needle position does not

change.

5.

Tighten the screw (3).

(1) - Lever

(2) - Bolt

(3) - Screw

(4) - Eccentric bolt

②

①

④

③

Summary of Contents for 52 i Series

Page 1: ...52Xi 52Xi 75 Service Instructions ...

Page 8: ...About these instructions 6 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 20: ...Working basis 18 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 74: ...Maintenance 72 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 76: ...Decommissioning 74 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 78: ...Disposal 76 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 83: ......