2.2

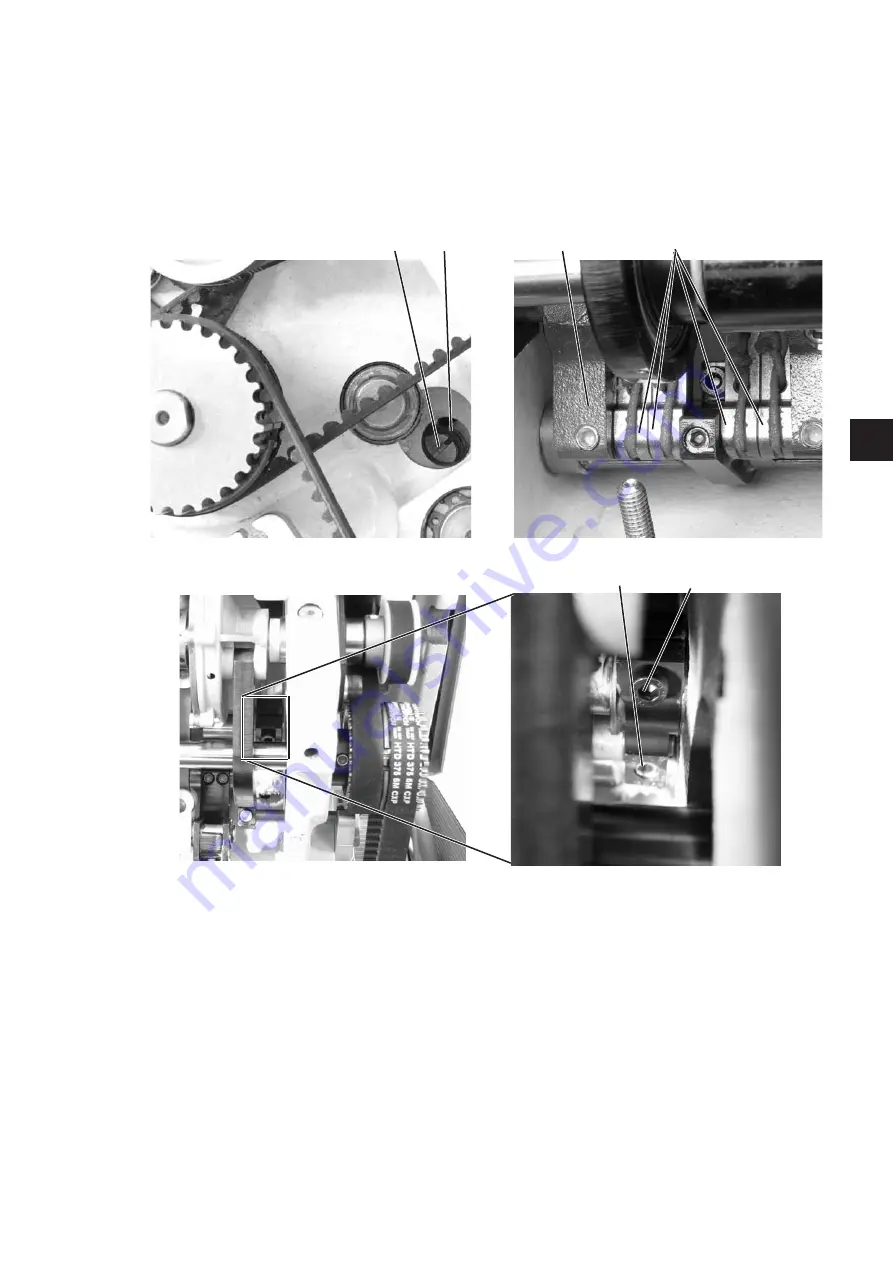

Stitch uniformity for forwards and reverse stitching

Rule:

1. When making a rough-scale adjustment to the stitch regulator gear,

the machine should not feed when the stitch length is set to “

0

”.

2. When making a fine-scale adjustment to the stitch regulator gear,

the forwards and reverse stitch lengths should only deviate in value

by a half stitch.

–

Set the stitch length to “

0

”.

–

Loosen screw (1) and turn the grooved (3) eccentric tappet (2)

according to the illustration. Fasten with screw (1).

–

Loosen screw (4) on the clamping lever. Turn the settings frame (5)

so that the shackles (6) are parallel. Tighten screw (4). This then

fulfils rule 1.

–

The next step is to match up the forwards and reverse stitch

lengths. Sew ten stitches forwards. Press the bartacking lever and

then sew ten stitches backwards. Rotate the eccentric tappet (2) so

that rule 2 is fulfilled.

–

Clockwise

= increase forward stitch, decrease

reverse stitch.

–

Counter-clockwise

= decrease forward stitch, increase

reverse stitch.

9

EN

2

3

5

6

1

4