966

1115,44

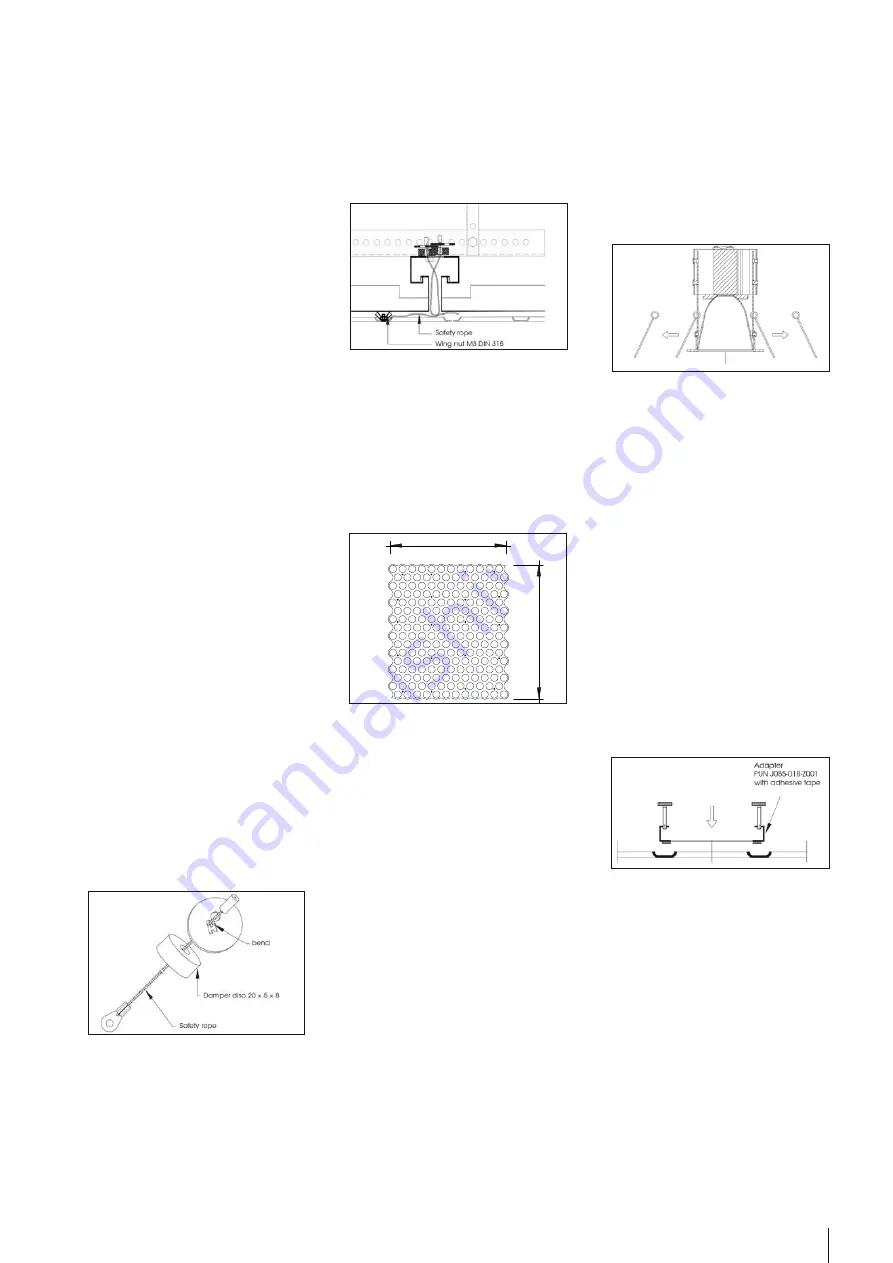

Beispielanordnung Magnete Standardelemente

5

© durlum GmbH | www.durlum.com | Subject to changes of dimensions and design. Errors reserved. All rights reserved. | Issued: 08.11.2016

4. When assembling the LOOP

®

elements,

the safety rope is screwed to the LOOP

®

element by means of a wing nut.

5. Measure the position of the LOOP

®

element exactly using the laser (longi-

tudinal and transverse rows). Hold the

LOOP

®

element with the rear magnet

(20 pieces per standard element) from

below horizontally against the ceiling

S7 KS (friction force by magnet). For

the arrangement of the magnets, see

below. To simplify assembly/disassem-

bly, the magnets can be glued to the

LOOP

®

element (e.g. LOCTITE).

6. The installation is then performed with

further elements similar to a puzzle.

The elements are to be aligned by sli-

ding them. To do so, the joints of the

LOOP

®

ceiling are aligned horizontally

by pushing or pulling the adjacent ele-

ment. Check the joint between the ele-

ments for flatness and uniform width.

7. For connection to the wall, the ele-

ments can be simply adapted to the

room, using a jigsaw. The cutting edge

is covered with a bracket or a plaster-

board frieze. In the area of the glass

wall, the cut is not covered. Ensure

clean cut.

MOUNTING OF LUMINAIRES

Note:

Mounting and electrical connection of the

luminaire must be performed by an autho-

rised skilled electrician (e.g. electric instal-

ler) in accordance with VDE 0100, taking

into account the technical information

and the legal regulations in force in your

country.

Safe operation of the luminaire is only gua-

ranteed if these instructions are observed.

This is why the mounting instructions should

be kept in a safe place. The manufacturer

cannot assume any liability whatsoever if

the instructions given below are not follo-

wed or the luminaire is used improperly.

1. Remove both springs of the

PUNTEO

®

-J85 LED downlight.

2. When fitting PUNTEO

®

-J85 LED down-

lights, a connecting adapter PUN J085-

018-Z001 is required, which is glued

centrally to the back of the element.

Attention: luminaires cannot be moun-

ted in the area of the secondary pro-

files!

3. Mount ballasts/drivers in the ceiling vo-

id, possibly on U 1040.

4. Perform electrical connection of the

driver.

5. Ensure that the LOOP

®

elements are

clean and free of grease. To fasten

the adapter PUN J085-018-Z001 to the

LOOP

®

element, a primer is required.

Note: The primer is not included in the

delivery. A primer for non-absorbent

substrates, e.g. EVT Primer MK, should

be used. Attach primer to the back of

the LOOP

®

in the glued area. Remove

the paper from the adhesive tape of

the LOOP

®

adapter PUN J085-018-Z001.

Then position and mount the adapter

on the back of the LOOP

®

element.

Press the adapter down firmly.

INSTALLATION MANUAL

LOOP

®

TYPE 3

ABBREVIATIONS

AH: Distance of the suspension hangers in

axial direction of the primary profile

AP: Distance of primary profiles U 1040

AS: Distance of secondary profiles W 2053-

ST

ASSEMBLY OF THE FALSE CEILING

Note:

Please take the S7 KS System Assembly in-

structions into account. With the following

exceptions:

Distannce of the primary profile <=800mm

Assembly of the suspension

Items 1-19 acc. to assembly instructions

Item 20

Cut the rail channel W 2053-ST to the requi-

red length.

Item 21

At the crossing points to the primary profi-

le, the rail channel W 2053-ST is screwed to

the L-shaped primary carrier U 1040 using a

self-securing screw connection M6.

Item 22

The joint formation of the rail channel is

performed using the rail channel connec-

tor W 2053-ST V.

Items 23 and 24 are withdrawn

ASSEMBLY OF LOOP

®

ELEMENTS

1. Wear clean cotton gloves.

2. Preassemble the safety ropes (min. 2 pi-

eces per standard element) as shown

on the drawing. Run rope through the

damper disc and safety rope anchor

disc and secure it in the armature disc

by bending the web.

3. Then run the preassembled rope

through an elongated hole (in the

area of the later fastening points of the

safety rope) in the rail channel out of

the ceiling void downwards.