- 19 -

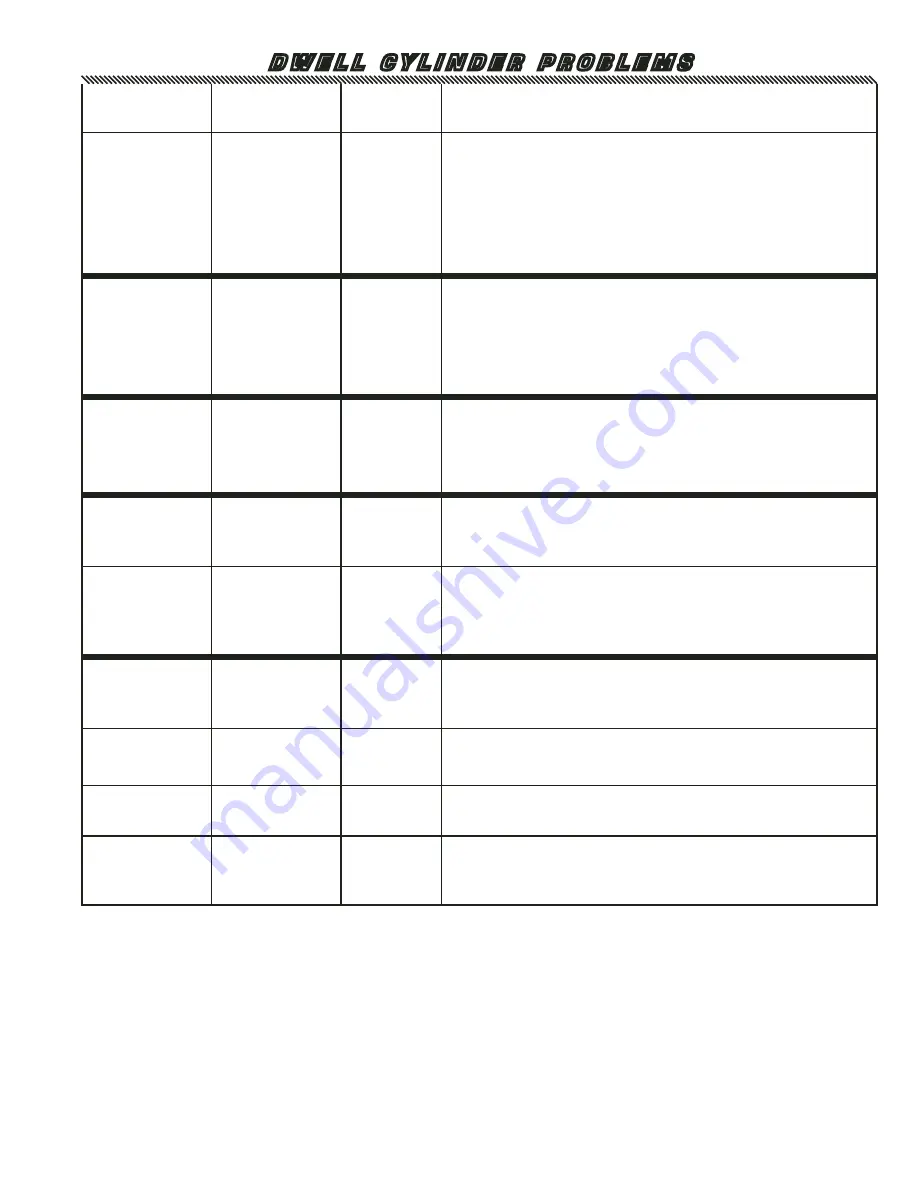

D W E L L C Y L I N D E R P R O B L E M S

SYMPTOM

CORRECT

FUNCTION

INDICATOR

POSSIBLE

PROBLEM

ACTION

Dwell cylinder does

not

retract and

weld stays on.

Initiate, Weld

timer, Feed

reed switch,

Dwell solenoid

and Weld signal

indicators

are all on

Constantly.

All lights flash in

sequence

Weld timer.

Remove the push-on connector from terminal #4 of the Weld timer. If Dwell

cylinder retracts and weld turns off replace Weld timer.

Dwell cylinder does

not retract and

weld stays on.

Initiate, Dwell

solenoid and

Weld signal

indicators

are all on

constantly.

All lights flash in

sequence

Short cycle

relay.

Test for voltage (24VAC+/-) at terminals #17 and #19. If the voltage is

present return to the step up above. If the voltage is not present,

now check the voltage (24VAC+/-) at the terminals #9 to #24, #18

to #22 and #17 to #22. If the voltage is present all the time on these

terminals replace the Short cycle relay.

Dwell cylinder does

not retract.

Dwell solenoid

and Dwell delay

indicators are

on constantly.

Dwell solenoid

indicator goes

on and off with

every cycle.

Stays on 150ms

longer than feed

reed indicator.

Dwell Delay

timer.

Remove the push-on connector from terminal #4 of the Dwell Delay timer.

If Dwell cylinder retracts replace the Dwell Delay timer.

Dwell cylinder does

not retract.

All indicators are

functioning

correctly

All lights flash in

sequence

(A) Dwell

solenoid.

(A) Turn the power off. (If the Dwell cylinder shaft retracts recheck symp-

tom). Now try and lift the cylinder shaft up. If the cylinder shaft cannot

be lifted replace the Dwell solenoid.

(B) Dwell

cylinder.

(B) If the cylinder shaft can be lifted easily check the Dwell cylinder and

air lines for air leaks. Turn the air off and then move the cylinder shaft

up and down. If the cylinder shaft moves up and down without any air

resistance the seals in the cylinder are most likely bad. Replace the

Dwell cylinder. If a slight air resistance is present on the up and down

motion replace the Dwell solenoid.

Sluggish movement

of the Welding tip.

All indicators are

functioning

correctly

All lights flash in

sequence

(A) Main air

regulator.

A) Adjust main air regulator (80psi).

(B) Air lines

and

Adjustable

mufflers.

(B) Check air lines for leaks or water in the air lines. If there is water in

the air lines, disconnect and blow out air lines. Remove and clean out

adjustable mufflers. Reconnect air lines and adjustable mufflers.

(C) Dwell

cylinder.

(C) Turn the power and air off. Check the Dwell Cylinder shaft for binding by

moving shaft in and out of the cylinder. A slight air resistance should be

present when the shaft is being moved in and out of the Cylinder.

(D) Dwell

solenoid

(D) If the above procedures check out and the Dwell cylinder still has

sluggish movement the problem maybe the Dwell solenoid. Remove the

air line from air inlet of the solenoid and spray a light oil in the solenoid.

Reconnect air line and cycle machine. If Dwell cylinder still has sluggish

movement replace the Dwell solenoid.

Summary of Contents for 14000

Page 13: ... 13 WIRING DIAGRAM FG MACH I ...

Page 14: ... 14 WIRING DIAGRAM FG MACH II ...