- 11 -

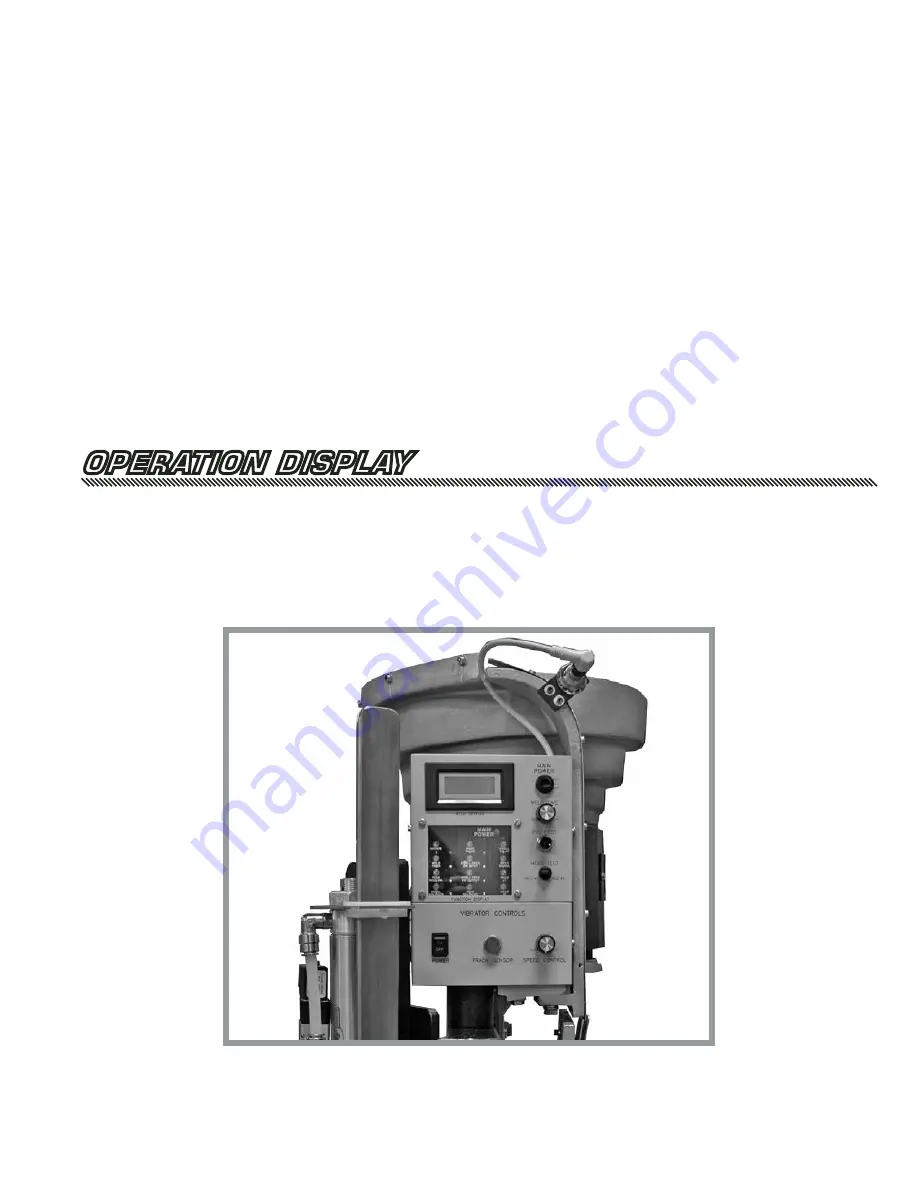

OPERATION DISPLAY

Your Mach I or Mach II Pinspotter is provided with an OPERATIONS DISPLAY to help identify the source

of the problem should your pinspotter fail to perform properly. Watching these lights will give you a clear in-

dication of the electrical flow of the various circuits and components during use. Should a problem arise, you

simply press the footswitch and watch to see which light fails to illuminate. A call to our Technical Services

Department at 1-800-899-3876 will quickly identify the faulty component for you to order or adjust.

STARTING OPERATION

1)

Never actuate the unit without metal over the mandrel. For maximum weld quality, the metal should be in

flat contact with the mandrel. An adjacent table or roller on which the sheet metal rests must be either

exactly flush with, or slightly below, the top of the mandrel.

2)

The WELD TIME controls the weld quality of the pinspotter. The display goes from 0 to 300. These num-

bers are for reference only and have no relationship with actual time. It is recommended that an initial

setting of 150 be used and then adjust up or down accordingly in reference to the quality of welds.

Weld time is the length of time the welding transformers are on. A fraction of a second is generally all

the time needed for a quality weld. Unnecessary weld time not only wastes energy but can also burn up

the pins. (If the pins glow red up to the washer, the weld time is set too high.) Always set the weld timer

to the minimum time required for a good weld.

3)

Before beginning production, always “pre-test” with smaller pieces of the same gauge sheet metal thickness

and liner density you intend to use in the final production. The different densities and the thicknesses of

the liner may require adjustments of the weld timer setting. For example: heavier gauge steel, thicker liner,

higher density liner and/or longer clip pins may require longer weld time. To make sure, always pre-test

any adjustment before you go into the “finished production.” However, only change the weld timer settings

when a change in the materials results in inefficient welding or a poor quality weld.