18

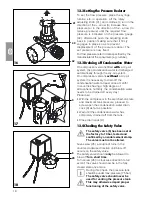

12.2 Setting the Pressure Reducer

To set the flow pressure, place the syringe,

turbine, etc. in operation. Lift the rotary

adjusting knob (41) and continue to turn in the

direction of the + arrow (to increase flow

pressure) or in the direction of the – arrow (to

reduce pressure) until the required flow

pressure is indicated on the pressure gauge

(42). Afterwards push the adjusting knob

back in position making sure that it firmly

engages in place so as to prevent

displacement of the pressure reducer. The

set pressure is now fixed.

For flow pressure refer to data specified by the

manufacturer of the consumers (e.g., turbine).

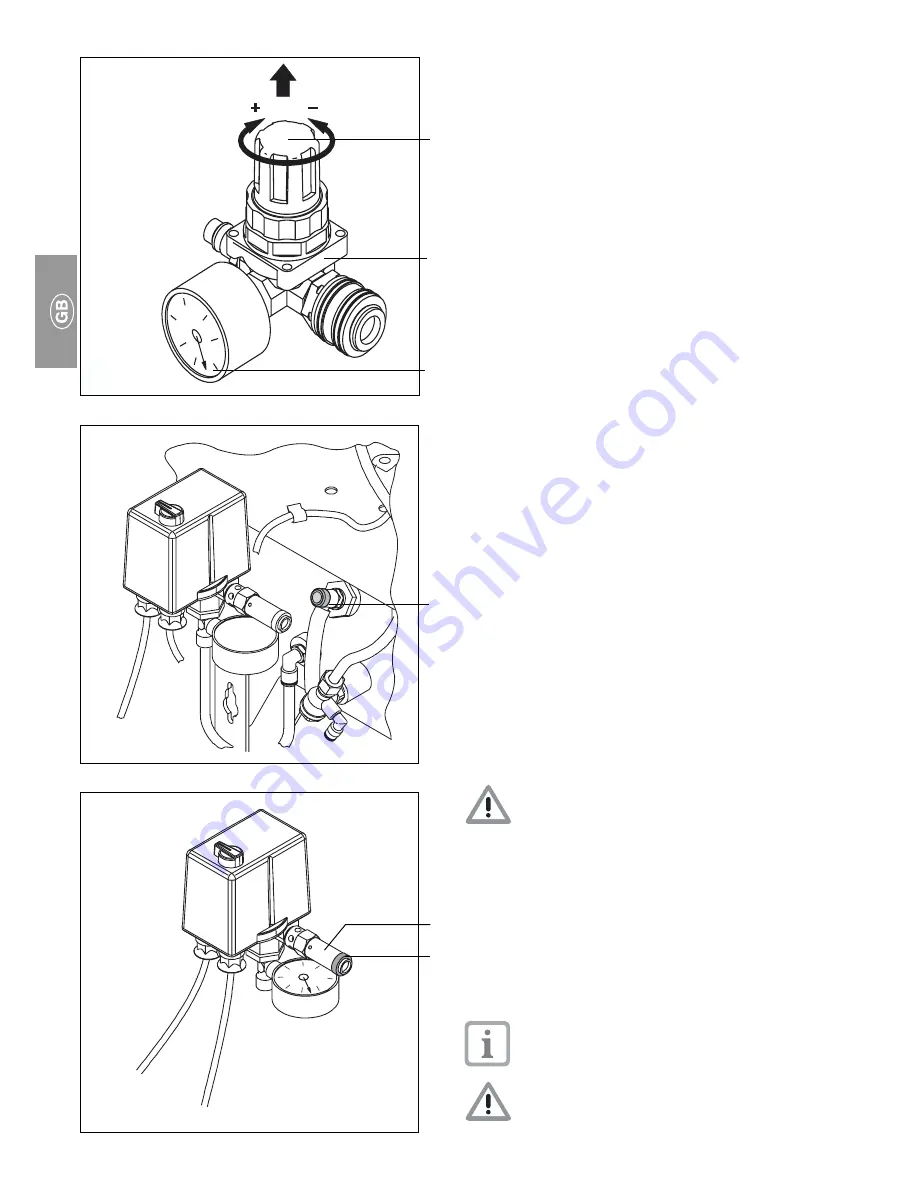

12.3 Draining off Condensation Water

On compressor versions fitted

with

a dry-air

system, the condensation water is discharged

automatically through the dry-air system.

On compressor versions

without

a dry-air

system it is necessary to drain off the

condensation water at least once a month!

In countries having a high degree of

atmospheric humidity, the condensation water

needs to be drained off every day!

Procedure:

• With the compressor in the switched-on state

and maximum tank pressure, proceed to

screw open the condensation-water drain

cock (9) as far as possible.

• Wait until the condensation water has

completely drained off from the tank.

• Close drain cock (9).

12.4 Checking the Safety Valve

The safety valve (6) has been set at

the factory to 10 bar, tested and

confirmed by an endorsement stamp.

The valve must not be altered.

Give screw (26) a couple of turns in the

counter-clockwise direction until blow-off

occurs on the safety valve.

The safety valve should

only

be allowed to

blow off

for a short time

.

Turn screw (26) in clockwise direction to full

extent; the valve should now be in the fully

closed state once more.

During this check, the pressure tank

should be under max. pressure (7.5 bar).

The safety valve should never be

used for venting the pressure tank.

This may otherwise impair proper

functioning of the safety valve.

16

40

41

42

9

17

18

26

6