1036100102L02 1904V002

19

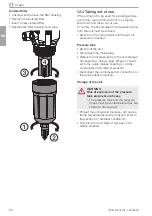

Assembly

8 Installation

8.1 Remove the transport locks

The unit is securely protected with two foam

blocks and a retaining strap for safe transport.

i

Cut and remove the retaining strap.

i

Remove the foam blocks.

i

Check the unit for damage in transit.

8.2 Establishing the compressed

air connection

The devices are designed as standard for

a nominal pressure of 7 bar. Exceeding

the nominal pressure on a regular basis

will reduce the service life of the device.

The unit is equipped as standard with a control

gear, which consists of a pressure switch, pres-

sure gauge, safety valve, non-return valve and

condensate drain.

In order to avoid the transfer of vibrations, we

recommend installing a flexible pressure hose

between the pressure hose and the pressure

switch. A pressure reducer can also be con-

nected.

i

The compressed-air supply is connected to

the quick-release coupling (incl. hose adapter

piece) or to the pressure switch by means of a

G 1/4" internal thread.

i

Secure the pressure hose to the hose adapter

piece using a hose clip.

i

Connect the hose adapter piece to the

quick-release coupling.

7 Transport

WARNING

Risk of explosion of the pressure

tank and pressure hoses

i

The pressure tank and the pressure

hoses must be vented before they are

stored or transported.

i

Protect the unit against moisture, dirt and ex-

treme temperatures during transport ("4 Tech-

nical data").

i

Always make sure that the condensate collec-

tor chamber is empty before transporting the

unit ("8.5 Draining the condensation water").

i

Always transport the unit in an upright posi-

tion.

i

Only transport the unit using the transport

handles provided.

i

Check the unit for transport damage.

EN

Summary of Contents for H2A-160M

Page 2: ......