32

1036100102L02 1904V002

Usage

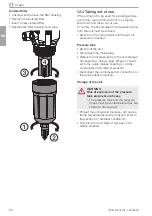

12 Maintenance

12.1 Maintenance schedule

Prior to working on the unit or in case of danger, disconnect it from the mains.

Unit without membrane-drying unit

NOTICE

Risk of damage to the unit due to blocked filters

Continuous running due to reduced delivery. Damage to the unit due to burst filters.

i

Replace filters in accordance with the maintenance schedule.

Maintenance

interval

Maintenance work

At regular inter-

vals

i

Drain the condensate from the pressure vessel by opening the condensate

drain valve (the interval can vary depending on the ambient conditions and

method of working; empty it daily with high air humidity).

Annually

i

Replace the air intake filter - every six months given a high concentration of

dust.

Every 4 years

i

Replace the vibration dampers.

In accordance

with national di-

rectives

i

Check the safety valve.

i

Carry out repeat safety tests (e.g. pressure vessel test, electrical safety test)

in accordance with the national directives.

Unit with membrane-drying unit

NOTICE

Risk of damage to the unit due to blocked filters

Continuous running due to reduced delivery. Damage to the unit due to burst filters.

i

Replace filters in accordance with the maintenance schedule.

Maintenance interval

Maintenance work

At regular intervals

i

Empty the collector tray under the membrane drying unit / condensate

drain (the interval may vary depending on the ambient conditions and

method of working; empty it daily if the humidity is high).

Annually

i

Replace the air intake filter - every six months given a high concentra-

tion of dust.

i

Change the 3 µm / 0.01 µm fine filter cartridge.

i

Replace the sintered filter.

Every 4 years

i

Replace the vibration dampers.

In accordance with na-

tional directives

i

Check the safety valve.

i

Carry out repeat safety tests (e.g. pressure vessel test, electrical safety

test) in accordance with the national directives.

EN

Summary of Contents for H2A-160M

Page 2: ......