1036100102L02 1904V002

35

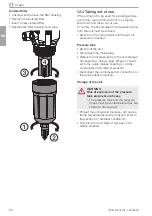

13 Tips for operators and service technicians

Any repairs exceeding routine maintenance may only be carried out by qualified personnel or

our service.

De-energise the unit prior to working on it or in the event of potential danger (e. g. pull the

mains plug) and prevent it from being switched back on again.

Fault

Probable cause

Solution

Compressor will not start

No mains voltage

i

Check the mains fuse; if neces-

sary, switch the circuit breaker

back on. If the fuse is defective,

replace it.

Undervoltage or overvoltage

i

Measure the mains voltage; call

an electrician if necessary.

Pressure switch not switched on

i

Switch on the pressure switch.

i

Inform a service technician.

Motor winding overheating pro-

tector tripped (overheating)

i

Allow the unit to cool down.

Humming noise from

motor

Motor capacitor is defective

i

Replace the capacitor.

The compressor does not

switch off

The compressor is too small, air

intake too high

i

Calculate the amount of air

required and install a larger

compressor if necessary.

Leakage in the compressed air

system

i

Locate and seal the leakage.

i

Inform a service technician.

Compressor switches on

from time to time even

though no air is being tak-

en for a consumer unit

Leak in the compressed air sys-

tem

i

Locate and seal the leak.

i

Inform a service technician.

Knocking or loud noises

on the compressor

Compressor unit defective

i

Disconnect all power from the

device and inform a service

technician.

Reduced delivery. The

compressor requires

longer to charge the pres-

sure vessel, see charging

times in "4 Technical data"

Air intake filter soiled

i

Replace the air intake filter at

least 1x per year. The air intake

filter must never be cleaned.

Water dripping from air

consumers

Maintenance work not carried out

regularly (without membrane dry-

ing unit)

i

Regularly drain the condensation

water from the pressure tank,

see "8.5 Draining the condensa-

tion water"

Defective membrane drying unit

i

Inform a service technician.

Troubleshooting

EN

Summary of Contents for H2A-160M

Page 2: ......