DANGER

The temperature switch may suffer

damage from a motor lockage or a

short circuit in the motor winding

Insufficient fuse protection of the electric

motors can result in fire, electric shock,

personal injury or material damage.

❯

Installation of a circuit breaker.

DANGER

Insufficient fuse protection of the

electric motors in unmonitored instal-

lations

Insufficient fuse protection of the electric

motors can result in fire, electric shock,

personal injury or material damage.

❯

Installation of a circuit breaker.

❯

The temperature switch must be con-

nected to a suitable relay.

7

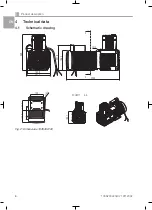

Commissioning

7.1

Remove the transport locks

The unit is securely protected with packaging

material to ensure safe transportation.

❯

Remove the packaging material.

❯

Remove the protective film.

❯

Check the unit for damage in transit.

7.2

Connect oil-free piston com-

pressor

Depending on the product, the units are

designed for a specific nominal pressure

(see "4.2 Technical data").

If this nominal pressure is exceeded, the

service life of the product is reduced.

The connections for the air inlet and air outlet are

located on the cylinder head. The atmospheric air

is drawn in via the air intake filter on the air inlet

side. On the air outlet side, the compressed air

flows through the air line to the consumer.

Air inlet

The air inlet opening is located on the cylinder

head. A suitable air intake filter must be mounted

on the air intake filter to preserve the service life

of the unit.

❯

The units are supplied with matching air intake

filters.

Air outlet

The air outlet opening is located on the T-piece

between the cylinder heads.

❯

Connect a pressure hose to the external thread

M16 x 1.5.

Operating the unit in a system

If the unit is installed in a system, the safety pres-

sure must not be exceeded (see "4 Technical

data"). Ensure that the safety pressure does not

exceed permissible overpressure values by pro-

viding of a safety device (e.g. safety valve,

solenoid valve etc.).

The operating or working pressure may not

exceed the nominal pressure of the unit. Acces-

sories for pressure control, e.g. pressure

switches and pressure reducers, are necessary in

order to ensure a constant mains pressure during

operation.

Depending on the application, control systems,

valve units, containers or other accessories are

required for safe operation.

Assembly

22

1035200220L02 1911V002

EN