66

0678106030L02 1411V002

The air is filtered during induction� This

does not alter the composition of the air�

The air induced should therefore be

kept free of harmful substances (e�g� do

not draw in air from a basement garage

or directly next to a suction machine)�

NOTICE

Risk of overheating due to insuffi-

cient ventilation

The unit produces heat� This can lead to

heat damage and/or to a reduction in

the service life of the unit�

• Do not cover the unit�

• Air must be able to flow in and out un-

obstructed�

• Ventilation openings must be suffi-

ciently large�

• For installed units, an independent

ventilation system may be required in

unfavourable cases�

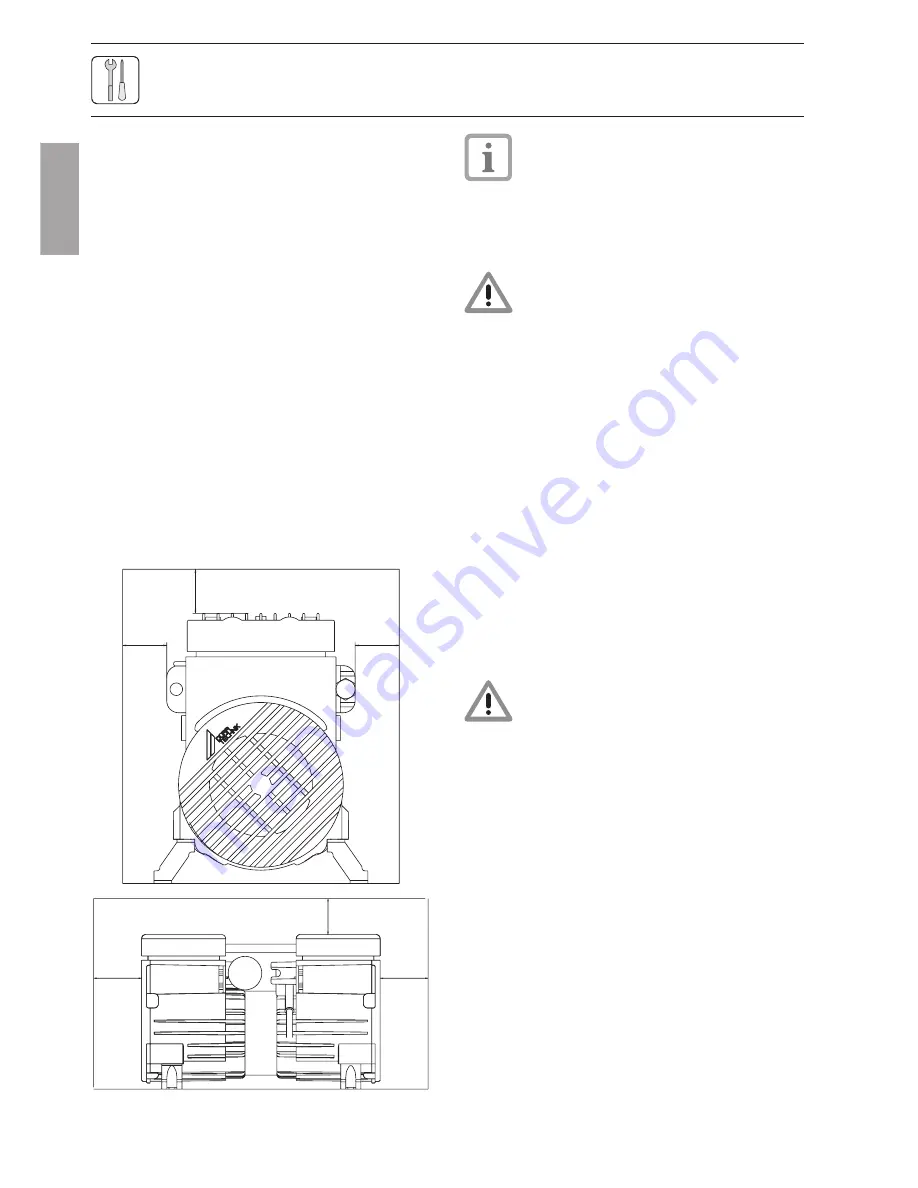

6.2 Vibration dampening

The units produce vibrations� Suitable vibration

dampers must be used to damp these vibra-

tions�

CAUTION

The use of rigid connections may

damage the units or the system in

which the units have been installed.

• Do not use rigid connection lines be-

tween the units and the system�

6.3 Installation position and fas-

tening

Install the units such that they are as level as

possible� Other installation positions must be

agreed in advance with Dürr Technik�

6 Prerequisites

6.1 Area of installation

The installation area must meet the following

requirements:

– Dry, well-ventilated room�

– Not a purpose-built room (e� g� heating or wet

room)�

– Set up the device on a clean, level and suf-

ficiently stable surface (observe the weight of

the device)�

– A socket outlet must be easily accessible�

– The type plate of the device must be easily

readable (also when installed)�

– The device must be easily accessible for

operation and maintenance�

– Once the devices are installed, the connect-

ing terminals must be easily accessible when

removing/opening the housing access�

– Maintain a sufficient distance from the wall

(min� 30 to 40 mm)�

30

30

30

40

40

30

Mounting

EN

Summary of Contents for KK15

Page 2: ......

Page 32: ...30 0678106030L02 1411V002 Product description G1 4 G1 8 Figure 14 KK15 Type A 035 62 EN ...

Page 87: ......