8

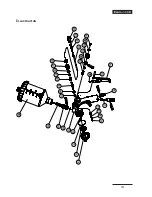

EcoGun 119

TECHNICAL PARAMETERS

Maximum allowed input air overpressure ....................4 bar

Operating air pressure - recommended* ............

1,8-2,5 bar

Air consumption* (LA, LW)

.......................250-300 Nl.min

-1

Air consumption* (LH) .............................300-400 Nl.min

-1

Power range of sprayed coating material* ..... 40-680 g.min

-1

Spraying distance * .......................................150-190 mm

Air quality:

– Max. dew point .....................................................+3°C

– Max. oil content ...............................................1 mg/m

3

– Max. size of solid particles......................................

5 μm

– Max. temperature ...............................................+40°C

Gun weight ............................................................487 g

Connecting sizes

– Air supply ..........................................................G 1/4“

– Supply of coating material ...................................G 3/8“

Environment classification

* It depends on size of nozzle assembly and type of application

material

II 2 GX

Summary of Contents for EcoGun 119

Page 2: ......

Page 23: ...23 EcoGun 119 ...