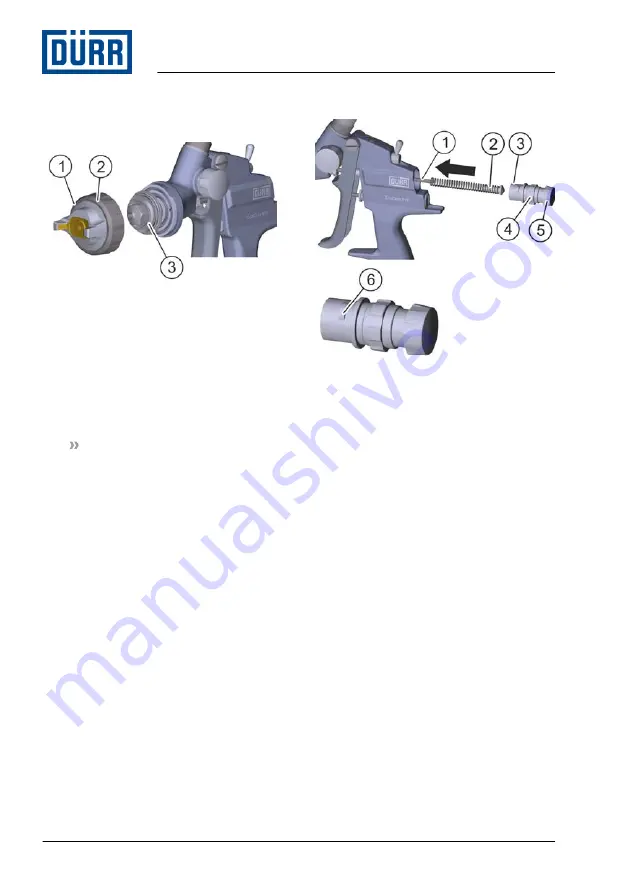

8. Pull out the needle (2) towards the back.

Dismantling the nozzle

Fig. 14: Dismantling the nozzle

9. Loosen the cap nut (2).

10. Pull off air cap (1).

11. Loosen nozzle (3) using a hexagonal

box wrench (13 mm) and remove it.

Installing the nozzle

12. Screw-in new nozzle (3) and tighten it.

Tightening torque: 18–20 Nm

13. Assemble and align the air cap

Inserting the needle

Fig. 15: Inserting the needle

14. Insert the needle (1).

15. Position compression spring (2).

16. Press stop screw (5) against the com-

pression spring into the body of the

spray gun. One of the nibs (6) of the clip

(3) must be in the 11 o’clock position.

17. Turn stop screw (5) clockwise until fas-

tened.

ð

Stop screw (5) is pushed back into its

initial position.

Faults

05/2018

EcoGun 910 - MSG00003EN

18/32