3

ENGLISH

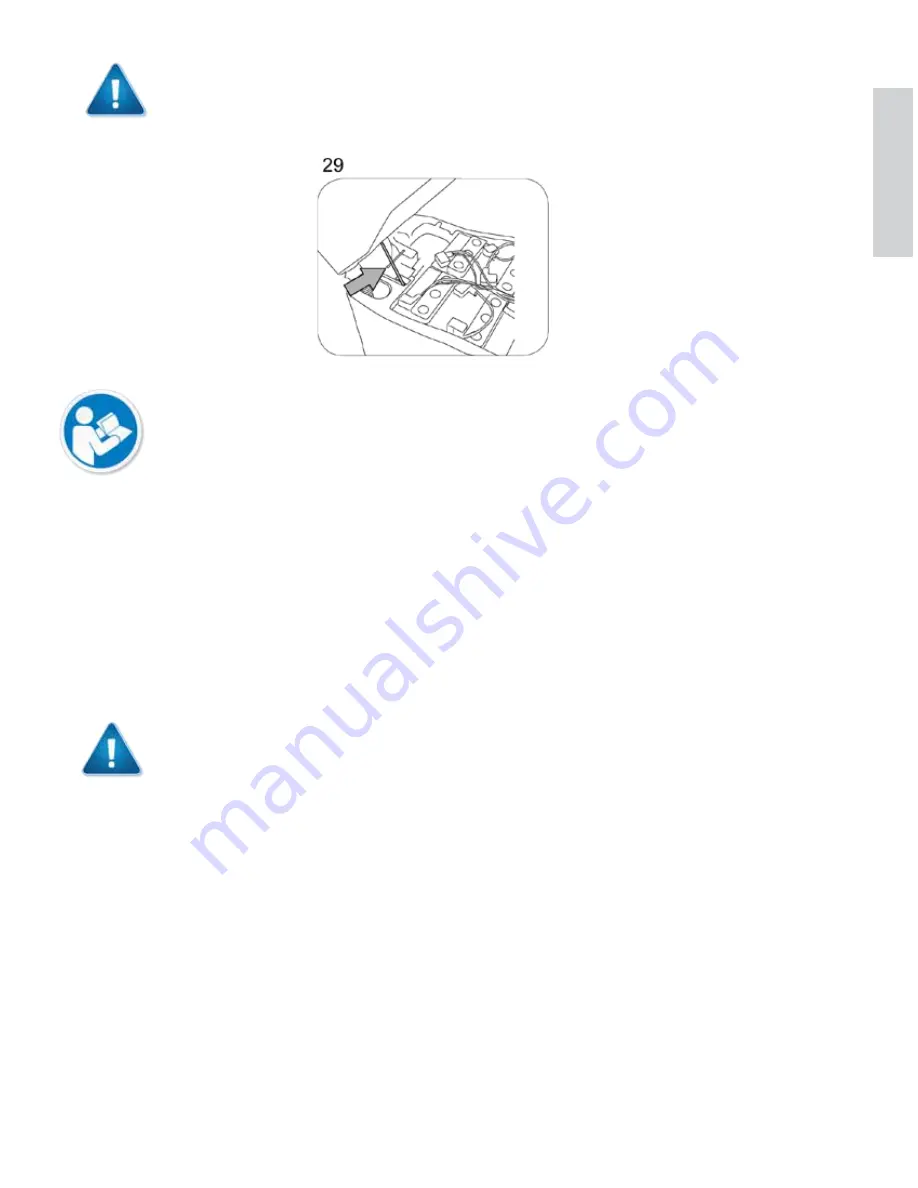

DANGER!

When lifting the dirty water tank (after having first been emptied) to access the compartment, the safety bracket must

be inserted in position, to stop the tank from accidentally closing again (Fig. 29).Only use original accessories and spare

parts supplied by the Manufacturer to guarantee safe and problem-free operation of the machine. Never use parts

removed from other machines or from other kits.

Movement

Installation

Lifting and transporting the packaged machine

WARNING:

During all lifting operations, make sure the packaged machine is firmly secured to avoid it tipping up or being accidentally

dropped. Always load/unload lorries in adequately illuminated areas.

The machine is packaged on a wooden pallet by the Manufacturer. It must be loaded on to the transporting vehicle using suitable

equipment (see EC Directive 89/392 and subsequent amendments and/or additions). At destination, it must be unloaded using

similar means. A fork lift truck must always be used to lift the packaged body of the machine. Handle with care to

avoid knocking or overturning the machine.

Delivery checks

When the carrier delivers the machine, make sure the packaging and machine are both whole and

undamaged. If the machine is damaged, make sure the carrier is aware of the damage and before

accepting the goods, reserve the right (in writing) to request compensation for the damage.

Unpacking

WARNING:

When unpacking the machine, the operator must be provided with the necessary personal protection devices (gloves,

goggles, etc.) to limit the risk of injury.

Proceed as follows to unpack the machine.

•

Cut and remove the plastic straps using scissors or nippers.

•

Remove the cardboard packaging.

•

Remove the bags from the battery compartment and check their contents: this Operator’s Manual, the maintenance

manual, declaration of conformity, certificate of warranty; battery bridges with terminals; connector for battery charger.

Depending on the model, remove the metal brackets or cut the plastic straps fixing the machine chassis to the pallet. Using a sloping

ramp, push the machine backwards off the pallet; see the paragraph “Pushing and pulling the machine” for details on engaging/

disengaging the electric brake on the drive wheel.

Unpack the brushes from their packaging. Clean the outside of the machine, taking care to respect safety regulations. Once the

machine is clear of the packaging, proceed to install the batteries (see the “Batteries: installation and connection” section). The

packaging may be kept and reused to protect the machine if it is moved to another site or to a repair workshop. Otherwise it must

be disposed of in compliance with current legislation.