4

ENGLISH

Batteries

Batteries: Preparation

DANGER:

During battery installation and any type of battery maintenance, the operator must be provided with the necessary

personal protection devices (gloves, goggles overalls, etc.) to limit the risk of injury. Keep clear of naked flames, avoid

short circuiting the battery poles, avoid sparks and do not smoke.

Batteries are normally supplied filled with acid and ready for use. If the batteries are dry, proceed as follows before installing them

in the machine.Remove the caps and fill all elements with sulphuric acid solution specific for batteries until the plates are entirely

covered (this requires at least a couple of passes for each element). Leave the batteries stand for 4-5 hours to allow air bubbles to

come to the surface and the plates to absorb the electrolyte.

Make sure the level of electrolyte is still above the plates and if necessary top up with sulphuric acid solution. Close the caps.

Install the batteries in the machine (following the procedure described below). Charge the batteries before starting up the machine

for the first time. Follow the instructions in the “Battery maintenance and charging” section.

Batteries: installation and connection

DANGER:

Check that all switches on the control panel are in the “0” (off) position. Make sure you connect the terminals

marked with a “+” to the positive poles of the battery.Do not check the battery charge by sparking. Meticulously

follow the instructions given below as short circuiting the batteries could cause them to explode.

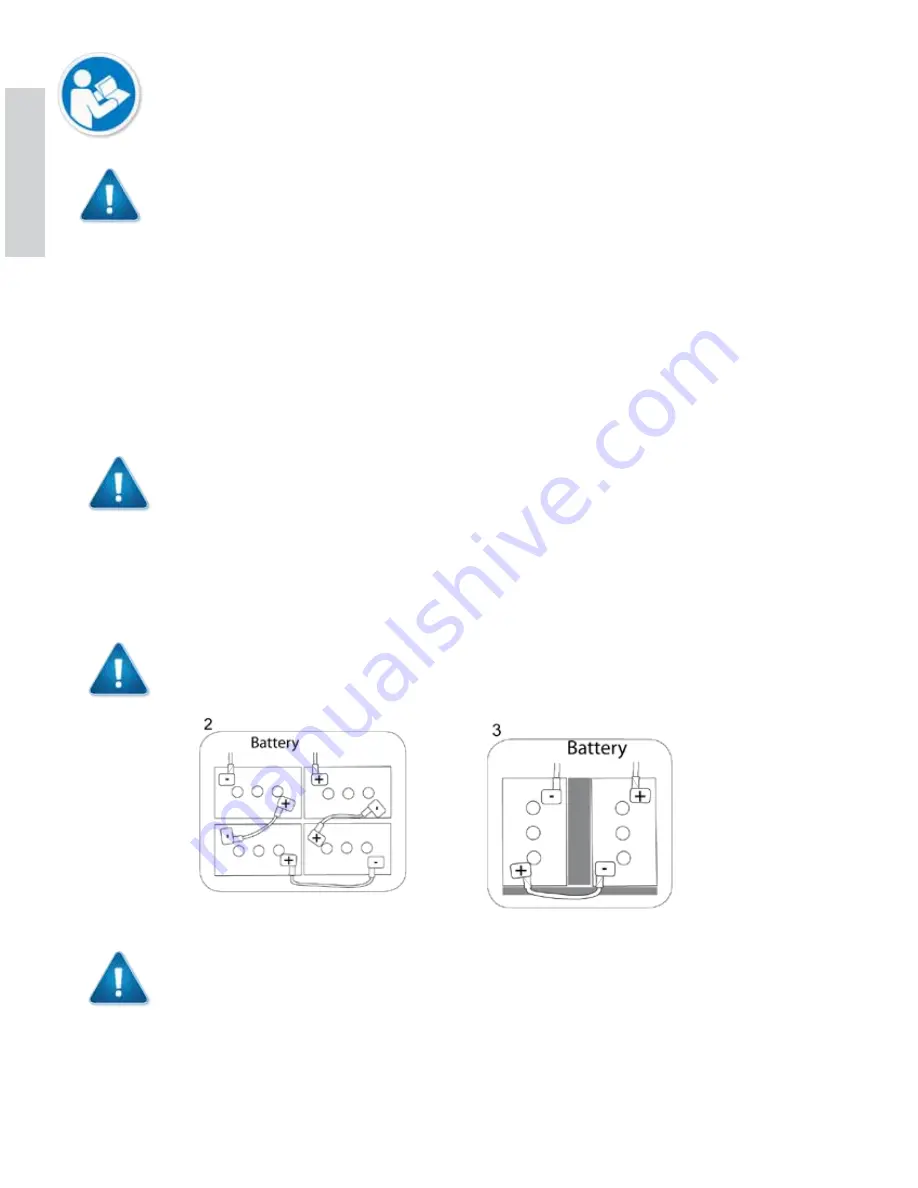

Place the batteries in the battery compartment, orienting them as shown in the drawings (figs. 2 and 3). On machines fitted with

two batteries, place the polystyrene spacers supplied between the compartment and the batteries, see the drawing (fig. 3) Referring

to the cable layout shown in the above diagram, connect the battery cables and bridge terminals to the battery poles. Arrange the

cables as shown in the diagram, tighten the terminals on the poles and coat with Vaseline. Lower the tank into the working position.

When using the machine, follow the instructions below.

WARNING:

Never allow the batteries to become excessively flat as this could damage them irreparably.

Batteries: removal

DANGER:

When removing the batteries, the operator must be equipped with suitable personal protection devices (gloves,

goggles, overalls, safety shoes, etc.) to reduce the risk of injury. Make sure the switches on the control panel ar

in the “0” position (off) and the machine is turned off. Keep away from naked flames, do not short circuit the

battery poles, do not cause sparks and do not smoke. Proceed as follows.

•

Disconnect the battery cables and bridge terminals from the battery poles.

•

If necessary, remove the devices fixing the battery to the base of the machine.

•

Lift the batteries from the compartment using suitable lifting equipment.