FREQUENCY CONTROL

PANELS

INSTALLATION, MAINTENANCE and OPERATION GUIDE

17

It is the process for the rotor speed of the motor to

reach its rated speed from zero. The stator of the motor

at stand stillWhen voltage is applied to its windings,

the induced back emf is zero. Because the rotor is

stationary. The current drawn at the first moment

is shortis the circuit current and this current is very

high. The force created by this current in the rotor

windings and the starting momentproduced and the

rotor starts to rotate with the effect of this moment.

The short-circuit current drawn over time causes the

motor to rotate.gets smaller as it starts. The opposite

of the machine or system connected to the shaft of

the engine and driven by the engine. When the torque

is equal to the torque produced by the motor, the

motor and the motor drive this system at constant

speed.continues to rotate. This operation is called

starting operation. Starting methods create a starting

torque, which is applied to the motor in order to bring

the motor to its speed at rated load. used to provide

sufficient current. Advantages and disadvantages of

each methodare available. Among them, frequency

converters provide the greatest energy savings.

The speed of a motor is directly proportional to the

frequency of the AC mains. Possible to adjust the

frequency of the network If it were possible, it would be

possible to control the speed of the engine. Frequency

converter to control the speed of the motorIt is a

method used for giving way. Frequency converters

include the input of fixed frequency AC power, variable

frequencylt is electronic devices that converts the

alternating current to an output by controlling the

frequency of the electrical power supplied to the

motor. They are used to control the rotating speed,

thus the speed of the engine.

In order for a three-phase asynchronous motor to

rotate at various speeds or at the same speed in

different conditions, a frequency inverter is needed to

be used. There are some advantages of using frequency

inverters to control the speed of asynchronous motors.

Big, strong motors consume high energy. Therefore, to

prevent this high energy consumption and to make

the motors rotate at desired speed in every condition,

panels with frequency inverters that generate various

frequencies and make the motor work at a stable

speed are produced. These panels work by adjusting

the speed at optimum conditions as the load requires.

Even the tiniest change in the speed can decrease

energy consumption at significant levels. The pump

runs at maximum speed at every condition when a

motor driver is not used. How ever, when a panel with

frequency control is used, energy can be saved by

decreasing the speed of the pump motor in the case

of water and need is decreased.

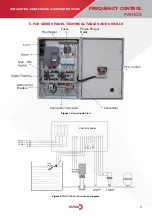

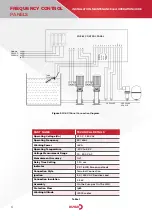

8. FREQUENCY CONTROLLED PANEL WORKING PRINCIPLE