FREQUENCY CONTROL

PANELS

INSTALLATION, MAINTENANCE and OPERATION GUIDE

3

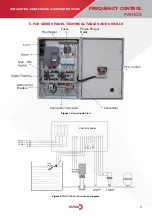

On The Control Panel The Speclal Securlty Equlpment

And Recommendations

May result in electrical shock or death.

In the wrong intervention to the control panel

may cause damage to the panel.

●

Control panel electronic card in order to protect from

extemal factors is made of plexiglass with a specially

designed insulation protection is available.

●

This protection panels and electronic card intervene

must not removed by unauthorized persons.

Efficient Use of Energy Saving Information

●

Pumps and motors energy-consuming products.

Personal causes and is extremely important for the

national economy.

●

Control panel suitable motor and pumps be used.

●

All electrical connections to the instructions by

providing appropriate and accurate; Be provided to

prevent any loss and leakage of electricity.

Usage Life

The product is determined by the Ministry of Industry

and declared usage life (time required to carry out the

functions of the appliance spare parts) 10 years.

1. TRANSPORT / STORAGE / MONTAGE

1.1 Transfer

●

Handle carefully control panels.

●

Appropriate size of the control panels are shipped in

cardboard boxes.

●

Do not remove the cardboard box inside the control

panels during transport.

1.2 Transport

●

Measure damage to the panel, and bad weather

conditions during transport should be taken to avoid

exposure.

●

Received by the panel in order to comply with the

model and should be checked for any damage during

transport.

●

If the clipboard contains a damaged or missing

damage assessment report should be given written

information to the shipping company our company.

1.3 Storage

●

Control panels of instead of immediately montage if not ;

●

Do not store in damp environments.

●

Do not put weight on the control panels.

●

Protect from direct sunlight at the control panels.

●

Keep out of the control panels watertight.

1.4 Montage

●

When performing mounting, follow the

Instructions otherwise It may be damaged

panels.

●

Montage are not observed instructions

during the that as a result of electric shock,

serious injury or death may result.

●

While mounting nuts at the rear of the control panel

should be mounted with suitable screws.

●

Do not mount the back of the board is drilled

with another screw. This may cause damage to the

electronic card.

●

Control panel electrical connection must be carried

out only by qualified personnel necessary safety

precautions.

2. OPERATING

●

Control panel electrical connections should be

checked.

●

The control panel should be checked that the cover is

closed.

●

There is power cut, the phases should be checked to

be complete.

●

Control panel settings to be used should be based

on pump or motor. Introduction to the settings

menu, you will find that you are using the appropriate

settings to the clipboard

3. MAINTENANCE

3.1 Monthly Maintenance

●

Disconnect electrical power before

maintenance operations.

●

Control panel electrical connections should be

checked relaxation.

The grounding line of the control

panel should be checked.

●

Electric cables, abrasion, puncture should be

examined for color change and warming.