A5-C

Sep ’15

- 8 -

Lubrication

Air End

Initial Start-up.

Each Compressor Unit built is extensively tested at

the factory before shipment. The Unit is shipped with

the original oil in it as used for testing purposes.

Check the Oil level and for any Oil leaks on a daily

basis. This must be done when the Unit is off. Top up

the Oil level on a monthly basis.

Use only DV Systems ‘

DEV-3000

’ Synthetic Oil.

Subsequent Oil Changes.

Drain the existing oil from the Unit. (Please be

advised that the Unit cannot be drained fully of oil, as

some oil may remain in various components ie

Cooler, Tubing, etc.)

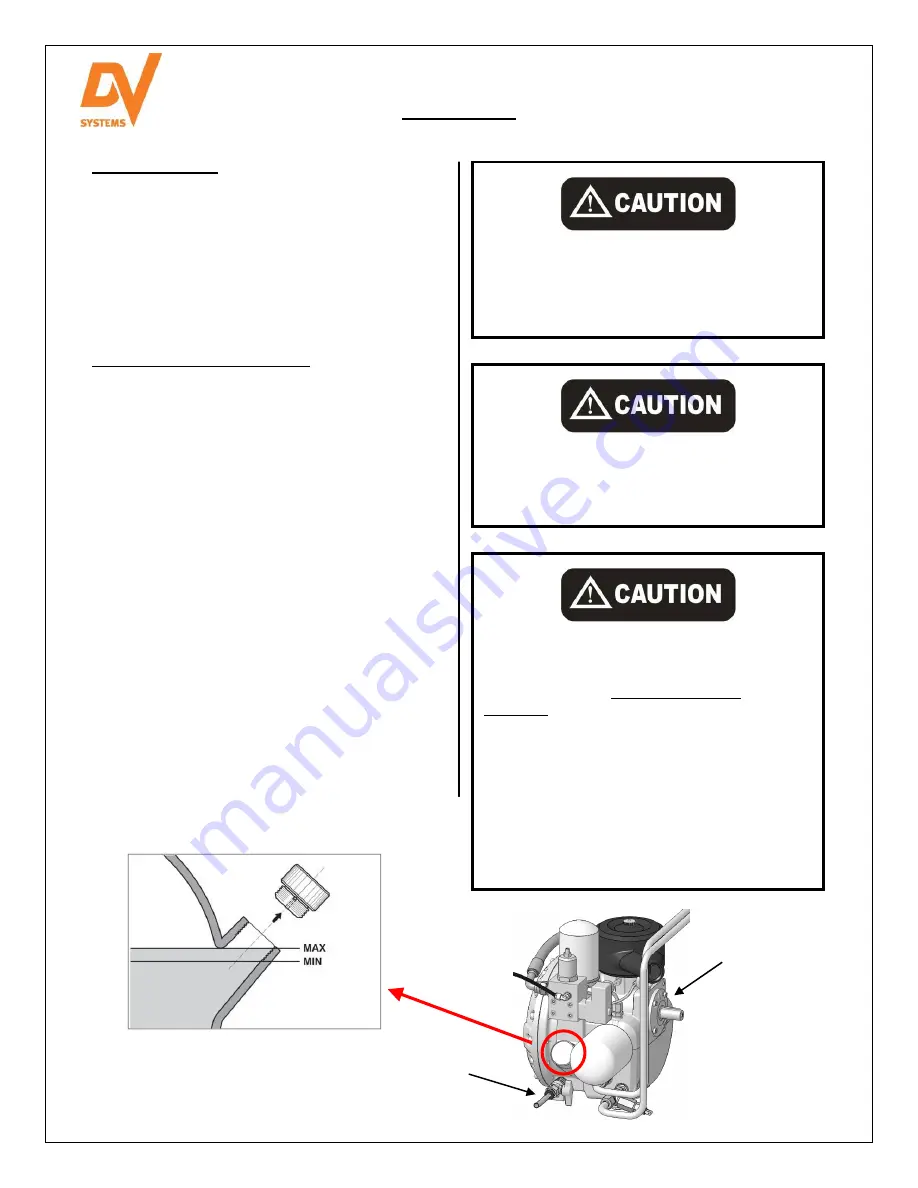

Fill the Oil Reservoir to the top of the Oil Fill Port as

shown below. Do not under or overfill. See drawing

below.

Use only DV Systems ‘

DEV-3000

’ Synthetic Oil,

available in both 1 US gallon (3.8 litre) jugs or 5 US

gallon (5 x 3.8 litre) pails. Any remaining oil may be

used for ‘top-ups’.‘

The ‘

MK-A5

’ Maintenance Kit includes:

(1) US Gallon (3.8 litre) Oil (‘DEV-3000’)

(1) Oil Filter (’DSC-603’)

(1) Air/Oil Separator Filter (’DSC-002832’)

(2) Air Filters (’DSC-001569’)

This Kit should be used in the regular servicing of

your Unit.

Do not attempt to operate the Unit without

first checking whether there is oil in the Air

End Reservoir. Add oil as required. Serious

damage may result from use, however

limited, without oil.

Use of improper oil may negatively affect

Compressor performance or shorten Unit life.

Resulting problems are not covered by the

DV Systems Inc. Air Compressor Warranty.

Condensation (water) may form in the Air End

if the compressor work cycle experiences

long pauses. If this occurs, the condensate

MUST be drained EVERY 50HRS OR

WEEKLY:

-

Wait for compressor to cool for approx.

2HRS.

-

Remove service panel

-

Slowly open the oil drain valve on the air

end & drain condensate

-

When the first traces of oil appear, close

the cap/valve

-

Top up the Air End with new oil using only

DV Systems ‘DEV-3000’ oil.

Oil Drain