HDI-03-W

Mar ‘15

- 10 -

Installation – Electrical (cont’d)

Motors.

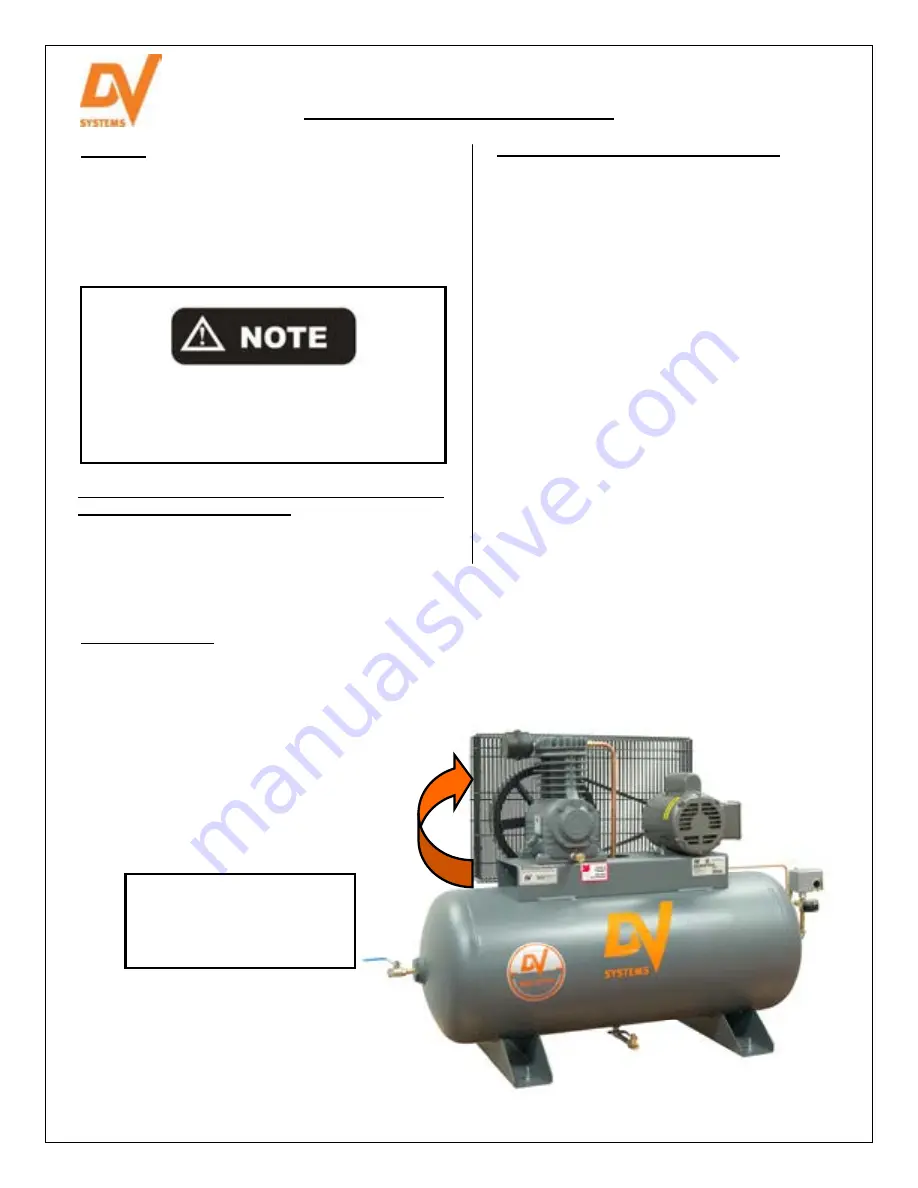

Pump Rotation.

The Compressor is to be wired in a manner that

the rotation of the Pumps Flywheel causes the air

to be blown from the Beltguard forward over the

Pump. This, coupled with the unobstructed area

behind the Beltguard of 18” (0.5 m) minimum,

allows the Pump to cool properly.

Ensure that the voltage on your site is reflected on the

Motor nameplate, +/- 10%. In the case of 208 volts 3

phase electrics, the Unit must be 200 volt

Use of an incorrect Motor for your particular

building service will result in premature Motor

failure, something not covered by the DV

Systems or Motor manufacturers Warranty.

The Warranty that exists on the Electric Motor is that of

the original Motor manufacturer. In the event of a Motor

failure, contact your DV Systems Distributor or Service

Centre for the location of the nearest authorized Motor

Service Centre.

Why Hire a Licensed Electrician?

To ensure that your new DV Systems Unit works as

designed and required, you must ensure that it is

correctly wired to your building service. It is the

responsibility of your Licensed Electrician to ensure

that:

The Unit you purchased is suitable for your

particular buildings electrical service.

Protective devices such as Magnetic Starters,

Fused Disconnects, etc have been sized and

installed correctly.

Any electrical accessories purchased with your

Compressor have been installed and wired

correctly.

The wiring of the Unit meets with all applicable

codes and regulations.

When completed, the Unit works in both a safe

and correct manner.

Failure of the Compressor Unit due to an incorrect

electrical installation is not covered by the

manufacturer’s warranty.

When facing the Compressor

(as shown at right), the

Flywheel must rotate in a

clockwise direction.