HDI-03-W

Mar ‘15

- 15 -

Compressed Air System Design

In designing a compressed air system, there are several factors that must be considered. Though cost may be a

factor in most designs, it cannot be the final determining factor, especially where air quality, air volume, and air

pressure are critical.

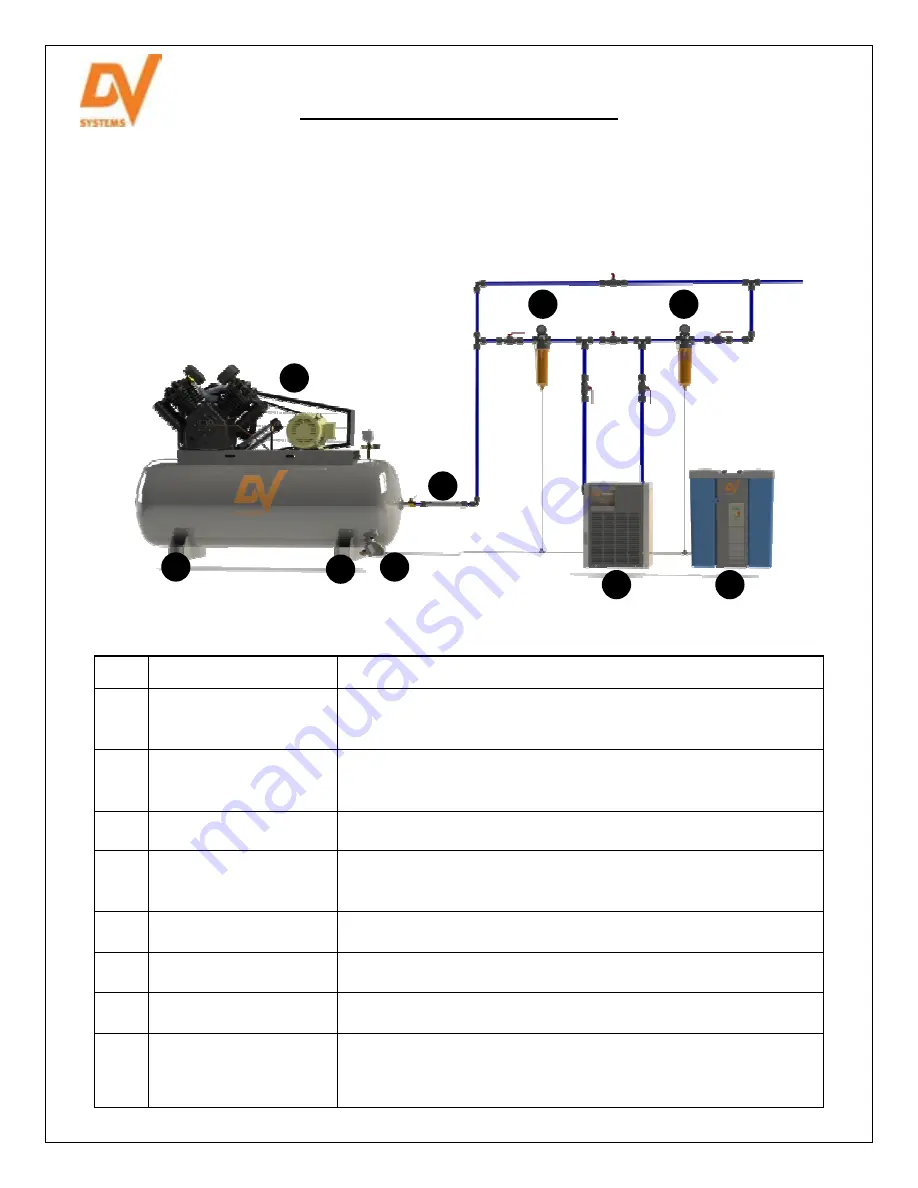

Shown below is a typical layout of a compressed air system.

Item: Component:

Description:

A

Air Compressor

Is the heart of the compressed air system. Ensure it is sized properly

for the application, installed in a correct and safe manner, and in

maintained according to the maintenance guidelines.

B

Vibration Isolators

Absorb any vibration caused by the normal operation of the Unit, allow

for any irregularities in the floor, and help to make the Unit marginally

quieter.

C

Automatic Drain

Drains the Compressor Tank on a regular basis. Available as either

pneumatic or electronic operated.

D

Flex Hose

Protects the building air lines from vibration caused by the

Compressor, and allows for any misalignment between the

Compressor outlet and building piping.

E

Separator Filter

Acts as a pre-filter to the Refrigerated Air Dryer. Generally a ‘Cyclone’

or 10 micron Filter.

F

Refrigerated Air Dryer

Removes the moisture from the compressed air by lowering the

temperature of the air to a few degrees above freezing.

G

Coalescing Filter

Removes oil from the compressed air. Available in 1.0 micron and

0.01 micron.

H

Oil Water Separator

Separates the oil from the moisture drained by the Compressor Tank,

Refrigerated Air Dryer, and Filters. Oil is trapped by internal Filters,

while the separated water is allowed to be dispensed to the building

drain.

G

E

F

A

B

C

D

H

B