SDI-W

Feb ‘19

- 1 -

Contents:

Page:

Safety Precautions

2

Preventative Maintenance Schedule

3

Unpacking and Inspection

4

Compressor Terminology

5

Installation – Mechanical

6

Lubrication

7

Installation - Electrical

8-9

Start-up Procedures

10

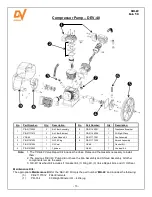

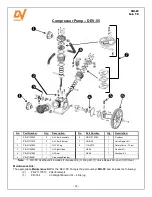

Compressor Unit Parts

11-12

Compressor Pumps

13-15

Trouble Shooting Guide

16-19

DV Systems Limited Warranty

20

Please read this manual before

installing or using your Air

Compressor Unit. It contains

valuable information that will

help in the receiving,

installation, use, and

maintenance of the Unit.

Please keep this manual in a

safe place for future reference.

All of the information, policies, and

procedures in this reference manual apply

exclusively to DV Systems.

DV Systems Inc.

490 Welham Road

Barrie, ON

L4N 8Z4

Tele: (705) 728-5657

Web: www.dvsystems.com

Email: sales@dvsystems.com

Standard Duty

Industrial

‘IS’ and ‘SDI’

Air Compressor

Installation,

Maintenance,

And

Service Data