Issue: 04.05.2011

DVZ-SKA-”BIOMASTER”-PLUS – Pump P2

Page 8 of 6

SKA-PLUS-ANNEX P2-Eng

Disassembly of the single action mechanical seal

- Pull the mechanical seal housing (214), together with the

atmospheric-side stationary seal face of the mechanical

seal (219), from the hollow shaft (125).

Note:

Particular care should be taken to ensure that the

housing, together with the stationary seal face, is pulled

off concentrically, without tilting, in order to avoid

damaging the stationary seal face.

- Press the stationary seal face and the O-ring out of the

mechanical seal housing (214). Ensure that the pressure

is evenly distributed.

- Drive out the retaining pin (220).

- Loosen the grub screws, if fitted, in the rotating part of the

mechanical seal housing (219), and pull the mechanical

seal from the hollow shaft (125).

ATTENTION

: Before loosening the grub screws, mark or

measure the position of the mechanical seal housing on

the hollow shaft. Do not push the O-rings over the drag

marks made by the grub screws.

Assembly of the progressive cavity pump

General

After careful cleaning, the particular pump parts are

assembled accordingly in reverse order.

Installation of the shaft seal

Installation of the gland packing

- Slide the gland housing (204) onto the hollow shaft with

the O-ring (235).

- Insert the gland packing (207) into the gland housing

(204). For shaft seal type P02, also insert the flushing

ring (208), and for types P03 and P04, also insert the

lantern ring (209).

Please see also Section „Fitting new packing rings“.

Installation of the mechanical seal (general)

Mechanical seals are high quality, precision-machined

parts. The mechanical seal manufacturer’s assembly

instructions must be observed. Careful handling and

extreme cleanliness during installation are essential for

proper functioning. To facilitate assembly, surfaces over

which O-rings slide can be lubricated with a suitable

lubricant, for example, silicon oil, Polydiol or soft soap.

ATTENTION:

Do not use ordinary oil.

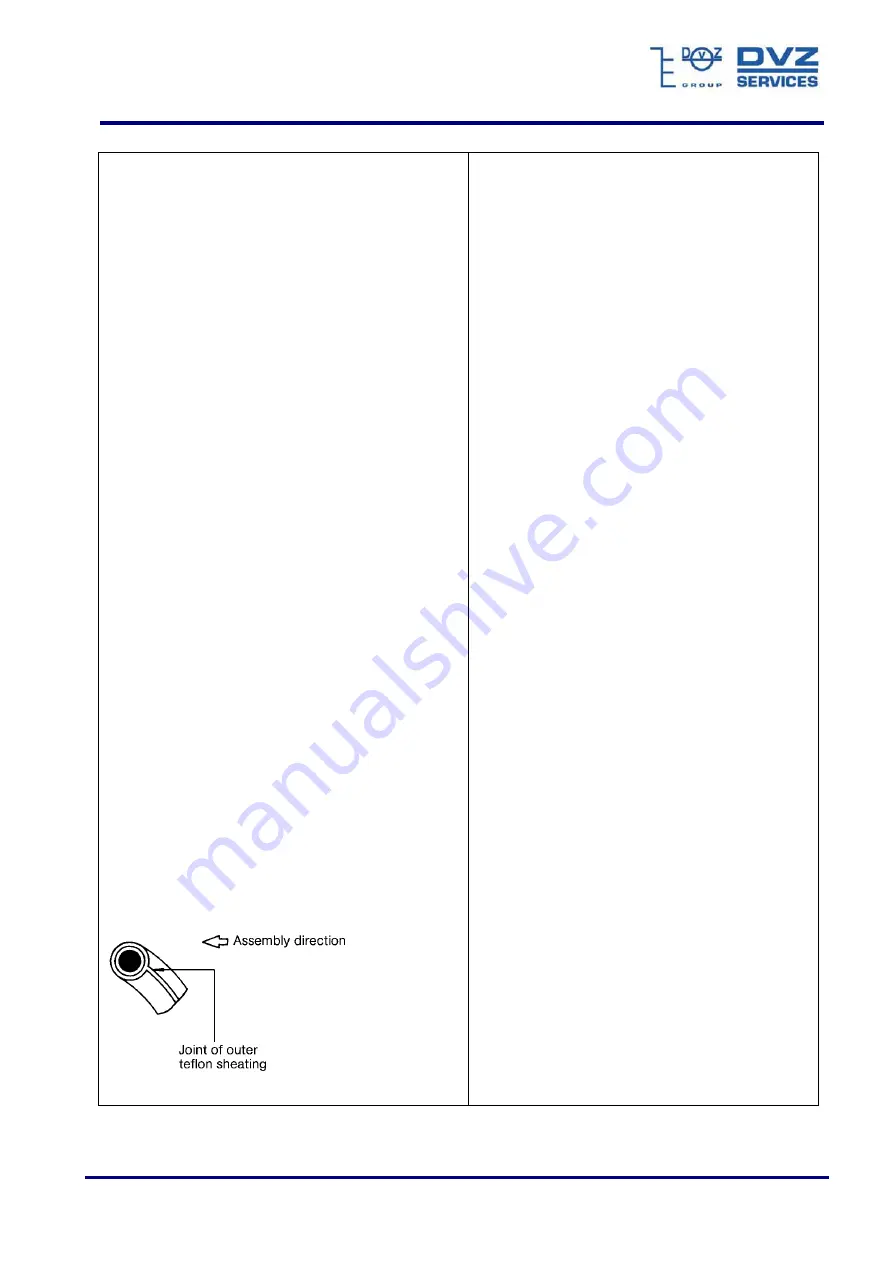

Note:

Parts that slide on top of one another must always

be exchanged in pairs. When using double PTFE sheathed

O-rings, please ensure that the joint of the outer sheathing

faces in the correct direction for assembly, as otherwise

the sheathing may open or be pulled off (see Figure 5).

Figure 5: Joint of outer teflon sheathing faces in the

correct direction for assembly.

Installation of single action mechanical seal

- Drive retaining pin (220) into the mechanical seal

housing (214).

- Press the stationary seal face (219), together with the

O-ring, concentrically into the cleaned seal housing

(214).

Note:

Ensure that the pressure is evenly distributed

and that the retaining pin (220) does not protrude

inside the mechanical seal housing.

- Push the rotating part of the mechanical seal (219)

over the hollow shaft (125).

Note:

Precisely observe the installation dimension

and/or position of the mechanical seal as marked

during disassembly.

- Insert the grub screws (if provided) into the rotating

part of the mechanical seal (219), using a liquid

retention agent such as Loctite no. 241, and tighten.

- Push the mechanical seal housing (214) together with

the stationary seal face (219) over the hollow shaft

(125).

Note:

Care should be taken not to tilt the mechanical

seal housing when pushing it onto the hollow shaft, in

order to avoid damaging the stationary seal face.

Installation of the hollow shaft

- The clamp sets (123) are delivered ready for

installation. They should not, therefore, be

disassembled before initial installation.

- Clamp sets (123) that have been removed do not

need to be disassembled and re-lubricated before re-

installation.

- Only clean and re-lubricate the clamp set (123) if it is

contaminated.

- A solid lubricant with a friction coefficient of µ= 0.04

must be used.

- If the conical surfaces are damaged, the clamp set

must be replaced.

- Grease the clamp bolt threads and the contact surface

of the heads with Molykote. Tighten the clamp bolts

manually, until the bolt heads are in full contact with

the inner ring of the clamp set.

ATTENTION:

Do not tighten the clamp bolts until the

hollow shaft (125) has been pushed over the shaft of

the drive.

ATTENTION:

Clean and degrease the shaft of the

drive and the bore of the hollow shaft (125).

- Slide the splash ring (123) onto the hollow shaft (125).

- Lightly grease the seat of the clamp set (123) on the

hollow shaft (125) and push the clamp set (123) onto

the hollow shaft (125) as far as the stop.

- Push the hollow shaft (125) onto the drive shaft as far

as the stop.

- Tighten the bolts of the clamp set (123) successively

in several turns, rotating the hollow shaft if necessary.

ATTENTION:

All clamp bolts must be tightened until

the front surfaces of the outer and inner rings are

flush and the fastening torque of the bolts increases

sharply (see operational condition in Figure 6). The

permissible fastening torque is marked on the clamp

set (123).

Summary of Contents for Biomaster PLUS Series

Page 15: ......

Page 16: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 83: ...Issue 16 08 2010 Instruction Manual DVZ SKA BIOMASTER PLUS Page 33 of 39...

Page 89: ...Issue 16 08 2010 Instruction Manual DVZ SKA BIOMASTER PLUS Page 39 of 39...