Thank you for choosing Super Weiye Handheld Welding Wire Feeding System. This user manual provides you with important

safety, operation, maintenance and other information. Therefore, please read this user manual carefully before using this

product.

In order to ensure safe operation and optimal operation of the product, please observe the following cautions and

warnings and other information in this manual.

I. Overview

This manual covers the basic installation, factory setting, operation and

maintenance service of this welding wire feed product and a general description of

each link.

The super welding wire feeding system is a wire feeding system launched in 2019.

The product covers the independent research and development control system, and

is equipped with the function of withdrawing and filling the wire. This product can be

adapted to various handheld welding wire feeding systems

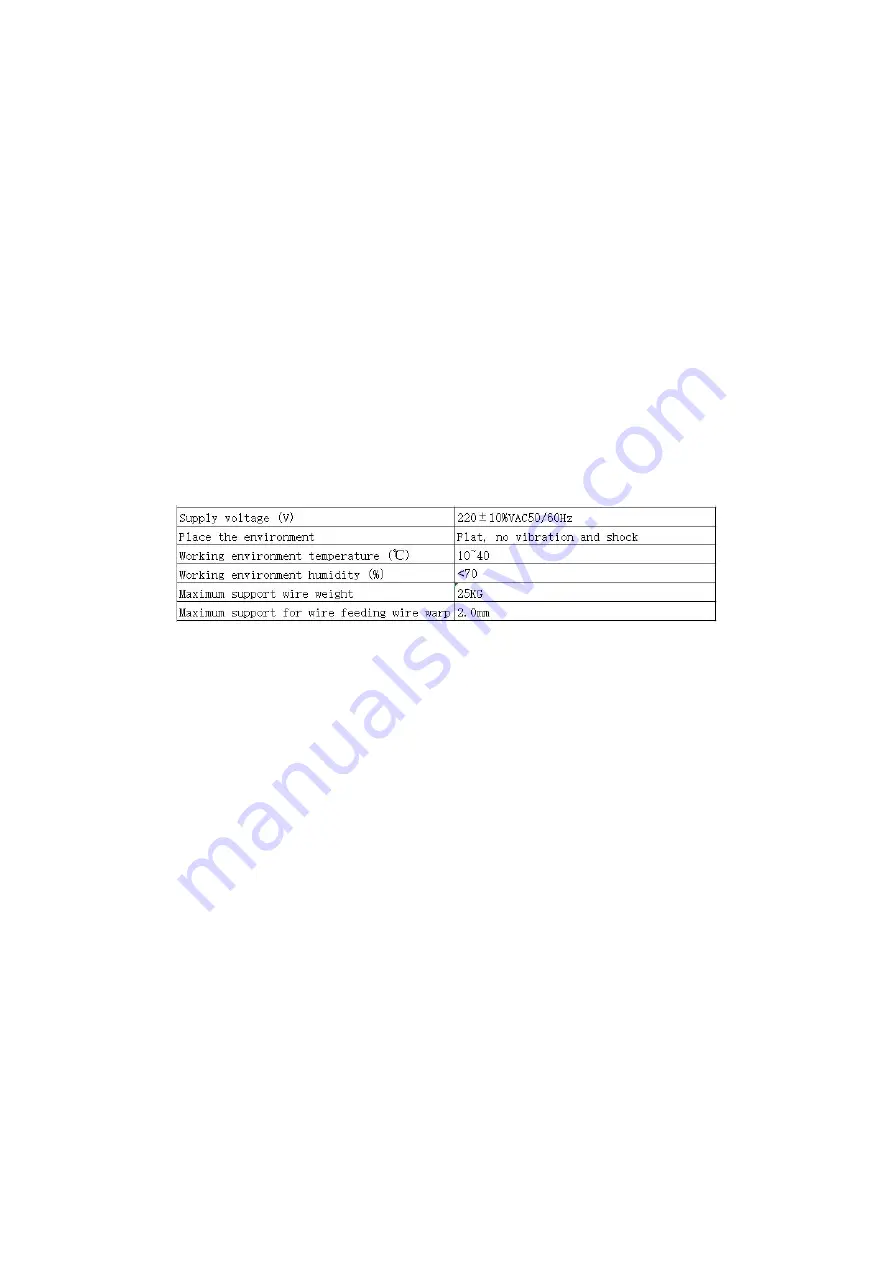

1.1 Operating environment and parameters

1.2 Attention information

1) Ensure reliable grounding before supplying power.

2) The wire feed wheel matches the wire warp and corresponds to the wire feed tube

3) Don't twist the wire feed tube

2. Installation

2.1 General definition of circuit wiring

2.1.1 The whole machine provides a three-core aviation plug, which is connected to

the three-core aviation plug at the tail of the wire feeder and provides 220V power

supply

2.1.2 The whole machine provides a two-core aviation plug, which is connected to

the wire feeding port of the control system to provide wire feeding signal (passive

contact, short-circuited wire feeding)