WHEATON® Standard Roller Apparatus

21

DWK Life Sciences | 856.825.1100 |

www.dwk.com

| P/N 50099786 Rev. 11/2021

5

MAINTENANCE – FOR QUALIFIED SERVICE PERSONNEL ONLY

DANGER!

NEVER ATTEMPT TO PERFORM REPAIRS IF THIS INSTRUMENT IS PLUGGED IN! IN

ORDER TO AVOID SERIOUS ELECTRIC SHOCK OR ELECTROCUTION, THIS INSTRUMENT MUST BE

DISCONNECTED FROM THE SOURCE OF AC POWER BEFORE IT IS WORKED ON.

Instrument Inspection

As with any piece of laboratory equipment, periodic inspection for worn and/or damaged parts

should be performed on a regular basis in order to maintain optimum performance. How often is

dependent upon usage, working environment, speed and possibly other special factors.

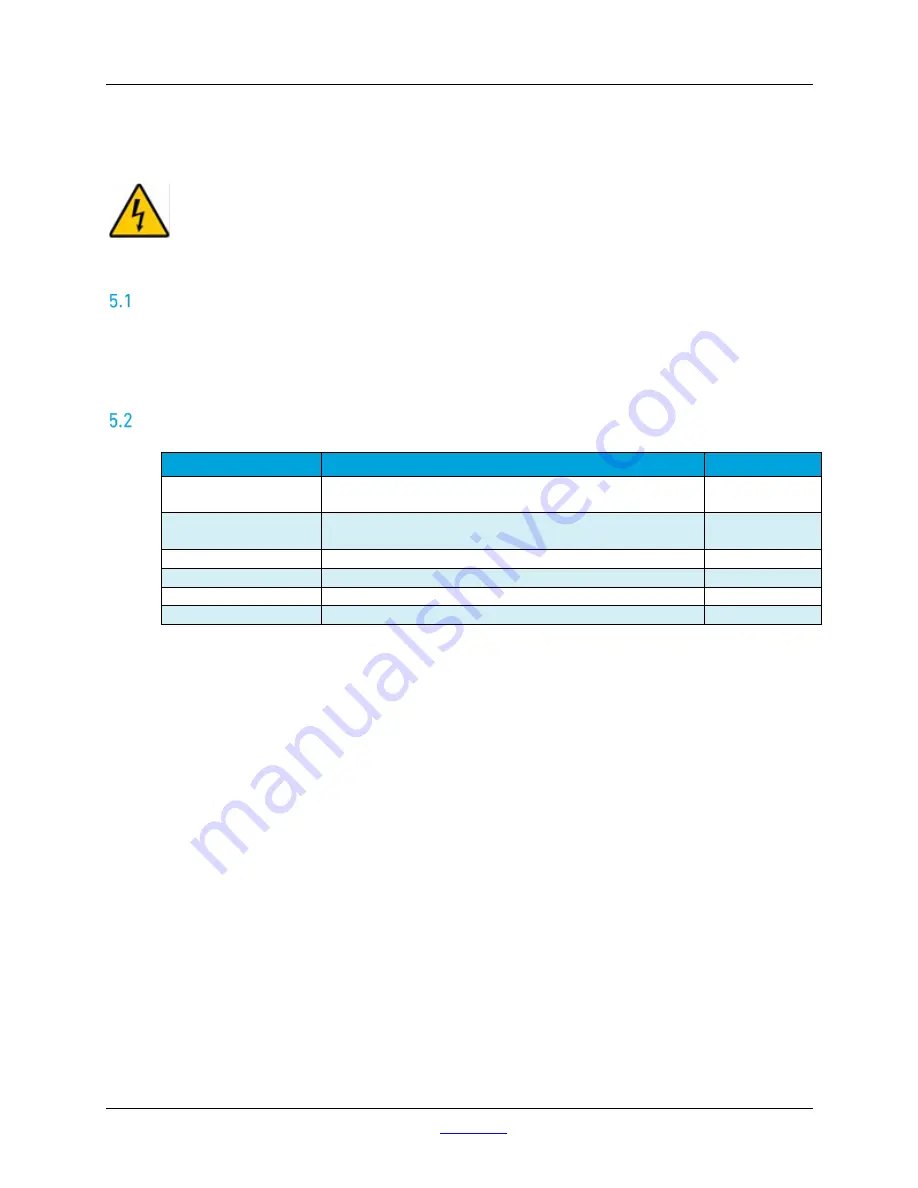

Instrument Maintenance Schedule

ITEM

ACTION

INTERVAL

Roller Bearings

Roller bearings are greaseless and require no lubrication.

Inspection is required for physical damage only

Once a year

Rubber Rollers

Check rollers for residue buildup. Rollers can be wiped

down with Alcohol or a common cleaning agent

At each harvest

interval

Nuts, Bolts, Hardware

Check for general tightness, replace missing hardware

Once a year

Drive Belts (black)

Replace belts if frayed or internal cords are showing

Once a year

Horizontal Belts (clear) Replace belts if excessively yellow or cracked

Every six months

Pulleys

Check for tightness on roller shafts, replace if damaged

Once a year

Roller Apparatus can be wiped down with a cloth dampened with Alcohol or a common cleaner. Use

of aggressive cleaners, such as Chlorine (Cl

2

) and Hydrogen Peroxide (H

2

O

2

), will reduce the lifespan

of the unit.

*

The use of vaporized disinfectants damages the electronics and is not authorized under the

warranty.

*