9 | Alarms and fault elimination

OPM BWT PERMAQ® Pico Rev. 2.0 EN

EN

46

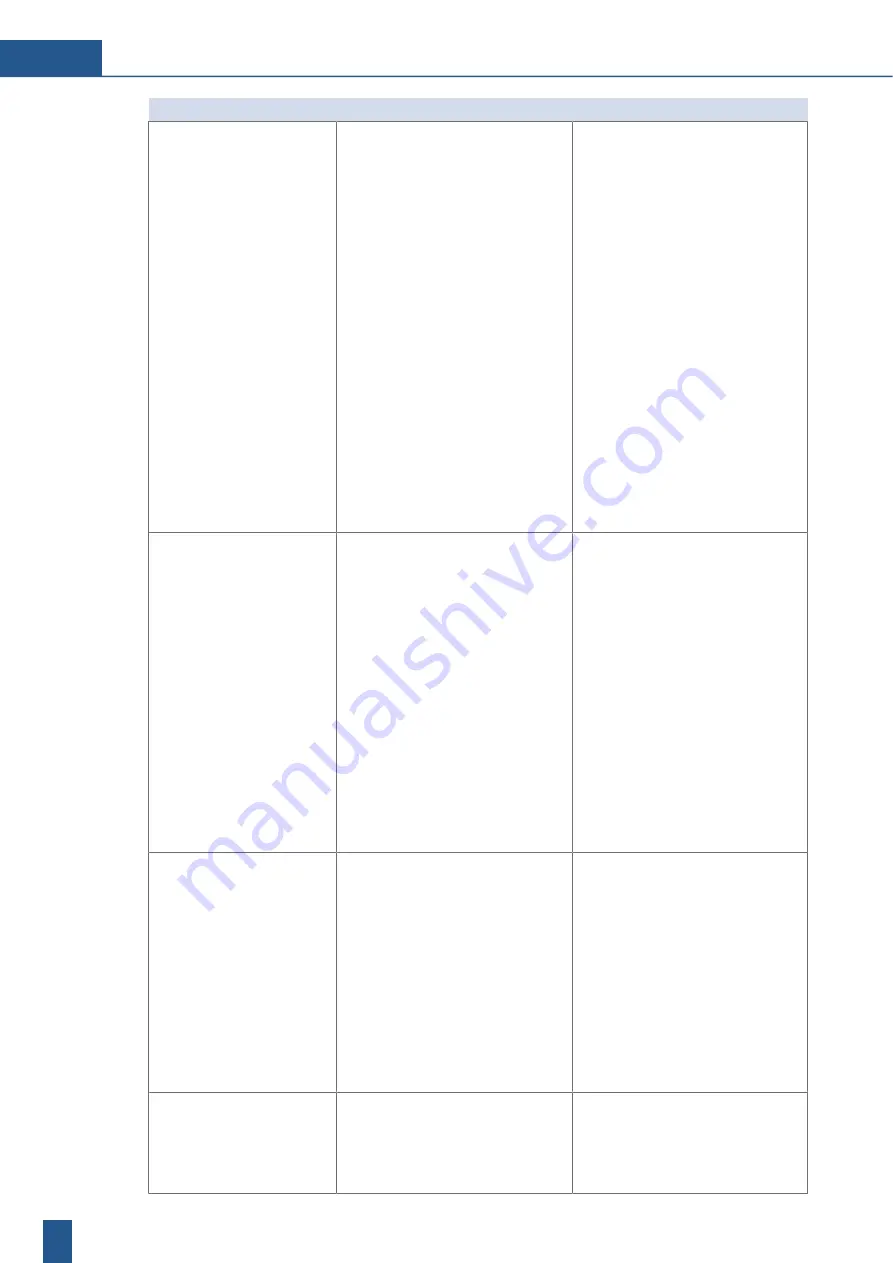

Alarm message

Possible cause

Possible corrective action

A2 COND1 perm. high

Alarm can be activated/

deactivated in the

SER-

VICE MENU

The maximum permissible

conductivity value has

been exceeded.

•

RO module(s) faulty

•

Fault on the upstream

softener (it does not regener-

ate correctly, salt residues

are still present in the

softener process)

•

Delay time for the alarm is

too low or the alarm limiting

value is set too low

•

Fault on the conductivity

probe, O-rings or check valve

•

Incorrectly programmed cell

constant or reference tem-

perature for the conductivity

measurement

•

PICO online: Pressure retain-

ing valve S21.07 is turned too

tightly, counter pressure is

too high (dilution effect due

to permeate backflow, the

pump is too low).

•

Ask for the BWT service team

and replace faulty RO mod-

ules if necessary

•

Determine the conductivity at

the outlet of the softener. We

recommend using a two-

column softener instead of a

single-column softener for

reasons of operational safety.

•

Check the delay time and in-

crease it if necessary (at least

one minute is recommended).

Adjust the alarm limiting

value if necessary

•

Readjust the counter pressure

on the pressure retaining

valve S21.07 if necessary

A2 COND2 extern.

high

(optional, second con-

ductivity probe)

Alarm can be activated/

deactivated in the

SER-

VICE MENU

The maximum permissible

conductivity of the ex-

ternal measurement (de-

salination) has been ex-

ceeded. Alarm is activ-

ated only if an external

measurement

A2 COND2

extern. high

has been

activated.

•

See

COND1

•

Incorrect setting during in-

stallation

•

Desalination cartridge is used

up and has to be replaced

•

See

COND1

•

Isolate the errors caused by

conductivity measurements in

the system and replace the

faulty components

•

Replace the desalination cart-

ridge

A2 Error bypass

Alarm can be activated/

deactivated in the

SER-

VICE MENU

The bypass opening time

exceeds the set maximum

value.

•

Consumption is constantly

higher than the permeate

supply

•

Loose connection between

the float sensor and terminal

•

Bypass OFF

float sensor is

faulty

•

Bypass function incorrectly

set to Y

•

Permissible bypass valve

opening time is too short in

the programme

•

Use a more powerful RO

•

Check the wiring

•

Ask for the BWT service

team; replace defective parts

•

Check the settings in the ser-

vice menu and adjust if ne-

cessary

A2 Terminal error

Alarm can be activated/

deactivated in the

SER-

VICE MENU

•

Display plug is disconnected

at the corresponding terminal

or contacts are detached at

the plug

•

Reconnect the plug or check

the wiring (specialist person-

nel)

•

Ask for the BWT service

team; replace defective parts