Model A-435-A Remote Display Tool

Specifications - Installation and Operating Instructions

Bulletin P-A-435-A

An option for Magnesense

®

II Differential Pressure Transmitter models that do not

have a display is to use a

Model A-435-A Remote Display Tool

which can plug into

the connector shown in Figure 1. The remote display tool has two buttons that function

identically to the buttons on the PCB.

CALIBRATION

Zero Calibration

In order to apply the zero calibration, vent both pressure ports to atmosphere or apply

equal pressure to both ports then press the zero button for 3 seconds. The display will

read

2Ero

and then sequence back to the home display. If the current reading is not

close enough to zero (±2%), the operation will fail and

FAIL

will be displayed.

SPAN Calibration

The span calibration can only be adjusted after completing the zero calibration. It

must be completed within 5 minutes of the last zero calibration. The span calibration

button will be ignored until the zero calibration is completed. Apply the maximum full-

scale pressure value, indicated by the DIP switch setting, to the positive pressure port

(i.e. the pressure value corresponding to 20 mA, 5 V, or 10 V depending on selected

output). Press and hold the span button for 3 seconds. The display will read

SPAn

and

then sequence back to the home display. If the span calibration is attempted before

adjusting the zero calibration, the

FAIL

error message will flash on the display. A failure

will also occur if the span operation is performed too closely to the zero point pressure.

Display Error Messages

ouEr

= The applied pressure is greater than the maximum span value causing an Over

Range Error.

UndEr

= The applied pressure is less than the minimum span value causing an Under

Range Error.

FAiL

= When the span or zero buttons are pressed, the pressure value is out of the

range to allow a correct setting. This may be due to a sensor failure or incorrect

pressure being applied.

Err1

= The sensor is damaged.

-rErr

= Negative display value too low to display.

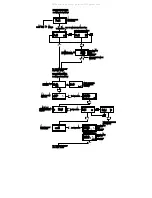

PROGRAMMING MENUS

Home Menu

During normal operation, the display will be in the Home Menu and will display the

current measured pressure and the engineering units.

Menu Access Security

While in the Home Menu, press and hold the Zero and Span buttons simultaneously

until

SECUr

appears on the display in order to access the other programming menus.

Upon releasing the buttons, the display will indicate the current security level.

If the current security level is the security level desired (i.e. Security Level 0), press

and hold the span button for three seconds to enter the Pressure, Velocity, or Air Flow

Menu.

If the security level is not the desired level, the security level can be changed

temporarily to a lower security level or permanently to a higher level of security by

pressing the zero button. A security code will be shown on the display and it can be

changed to one of the codes listed in the below table. The span button chooses which

digit and the zero button increments the value of that digit. Pressing and holding the

span button will store the value.

The level of access to the programming menus and the calibration is limited based on

the security level. The above table details the level of access for each security level.

Security

Level

Setting

Access

View Menu Edit Menu Span Zero

0

1

2

3

000

111

222

333

Yes

Yes

No

No

Yes

No

No

No

Yes

No

No

No

Yes

Yes

Yes

No

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Once the zero or span calibration button is released, there is a 5

second delay before the change takes effect. This delay is used to

prevent stress related offsets on the lower ranges.

NOTICE

The security level that is set in the Programming Menu Section

of the manual will determine which calibrations, if any, may be

adjusted by the user.

NOTICE

All manuals and user guides at all-guides.com