Series CDTA Communicating Carbon Dioxide Detector

Specifications - Installation and Operating Instructions

Bulletin AQ-CDTA-QS

The

Series CDTA Communicating Carbon Dioxide Detector

combines the function

of three room sensors into a single, compact housing. Parameters include carbon

dioxide, humidity, temperature, and temperature set point with override. By having

field selectable Modbus® and BACnet Communications, only four wires are needed

for power and the communication signal. The communicating detectors can be daisy-

chained together to further reduce installation cost. In order to reduce the set up time,

the RS-485 MAC address is set up using on board dip switches. A second set of

dip switches are used to select whether output is Modbus® RTU or BACnet MS/TP

communication protocols and to limit access to the set up menu.

Like our Series CDT Carbon Dioxide Transmitter, the Series CDTA uses a Single

Beam Dual Wavelength Non-Dispersive Infrared (NDIR) sensor to measure the carbon

dioxide level. This technology can be used in installations that will be occupied 24

hours per day. For improved accuracy, the transmitter can be field calibrated to the

environmental conditions of the installation. Also, the barometric pressure can be

programmed to correct for altitude. The humidity uses a capacitive polymer sensor and

the temperature is measured using a 10KΩ thermistor sensor. The humidity sensor is

field replaceable without the need for additional calibration.

Optional local and remote displays are available to display any of the parameters. For

applications in which the building occupants aren’t familiar with CO

2

concentrations,

the LCD can be programmed to display temperature, humidity, or temperature set

point instead.

Installation

SPECIFICATIONS

Sensor (CO

2

):

Single-beam, dual-wavelength NDIR; Humidity: Capacitive polymer;

Temperature: Solid state band gap.

Range:

CO

2

: 0 to 2000 or 5000 PPM CO

2

(depending on model); Humidity: 0 to

100% RH; Temperature: 32 to 122°F (0 to 50°C).

Accuracy:

CO

2

: ±40 ppm ±3% of reading; RH: ±2% (10 to 90% RH); Temperature:

±1°C @ 25°C.

Temperature Dependence (CO

2

):

±8 ppm / °C at 1100 ppm.

Non-Linearity (CO

2

):

16 ppm.

Pressure Dependence (CO

2

):

0.13% of reading per mm of Hg.

Response Time (CO

2

):

2 minutes for 99% step change.

Temperature Limits:

32 to 122°F (0 to 50°C).

Humidity Limits:

10 to 95% RH (non-condensing).

Power Requirements:

10 to 42 VDC / 10 to 30 VAC.

Power Consumption:

Average: 0.5 watts; Peak: 1.2 watts.

Output:

2-wire RS-485, Modbus

®

RTU or BACnet MS/TP communication protocol.

Weight:

4.4 oz (125 g).

Agency Approvals:

BTL, CE.

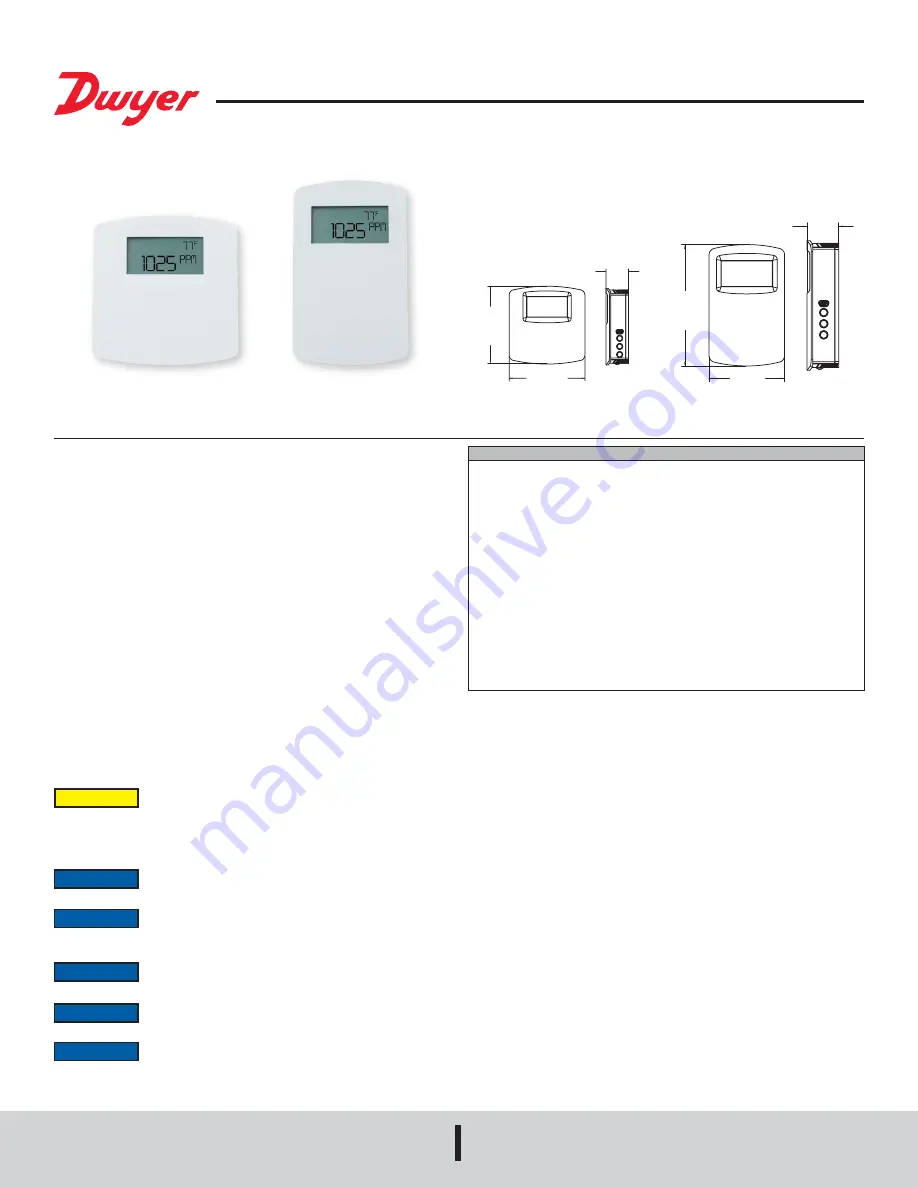

European style

North American style

1.08

[27.33]

1.10

[27.96]

4.50

[114.30]

2.80

[71.12]

3.65

[92.72]

3.56

[90.42]

Use electrostatic discharge precautions (e.g., use of wrist straps)

during installation and wiring to prevent equipment damage.

For optimal performance, self calibration feature of the transmitter

requires exposure to normal outdoor equivalent carbon dioxide

level once every thirty days.

Avoid locations where severe shock or vibration, excessive

moisture or corrosive fumes are present.

Do not exceed ratings of this device, permanent damage not

covered by warranty may result.

Upon powering the transmitter, the firmware version will flash on

the display. A warm up period of 30 minutes is required for the

transmitter to adjust to the current CO

2

concentration.

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

Disconnect power supply before installation to prevent electrical

shock and equipment damage.

Make sure all connections are in accordance with the job wiring diagram and in

accordance with national and local electrical codes. Use copper conductors only.

CAUTION

Modbus

®

is a registered trademark of Schneider Automation, Inc.

®

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com