Printed in U.S.A. 3/19

FR# 444131-00 Rev. 2

©Copyright 2019 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

CO2 Offset (OFC)

This value allows the CO

2

Concentration to be adjusted by a fixed amount to match

another calibrated measurement. The display shows the current CO

2

concentration

value plus any previous offset value.

Auto Serial Configuration (AUT)

This value enables or disables the automatic baud rate detection. If the device fails

to communicate on the MS/TP bus or the serial configuration is not 8 data bits, no

parity and 1 stop bit, then this value should be set to “OFF”, and the serial configured

manually.

Baud Rate (BAU)

This value provides the selection of the desired serial baud rate. This value is only

visible when the value of AUT is “OFF”.

Parity Selection (PAR)

This value provides the selection of the desired serial parity. This value is only visible

when the value of AUT is “OFF”.

Stop Bits Selection (STP)

This value provides the selection of the desired serial stop bits. This value is only

visible when he value of AUT is “OFF”

Reset To Factory Defaults (RST)

This value, when set to “YES”, will reset all user settings to their default values and

reset the device. This applies to all settings including BACnet writable settings.

Calibrating Sensor

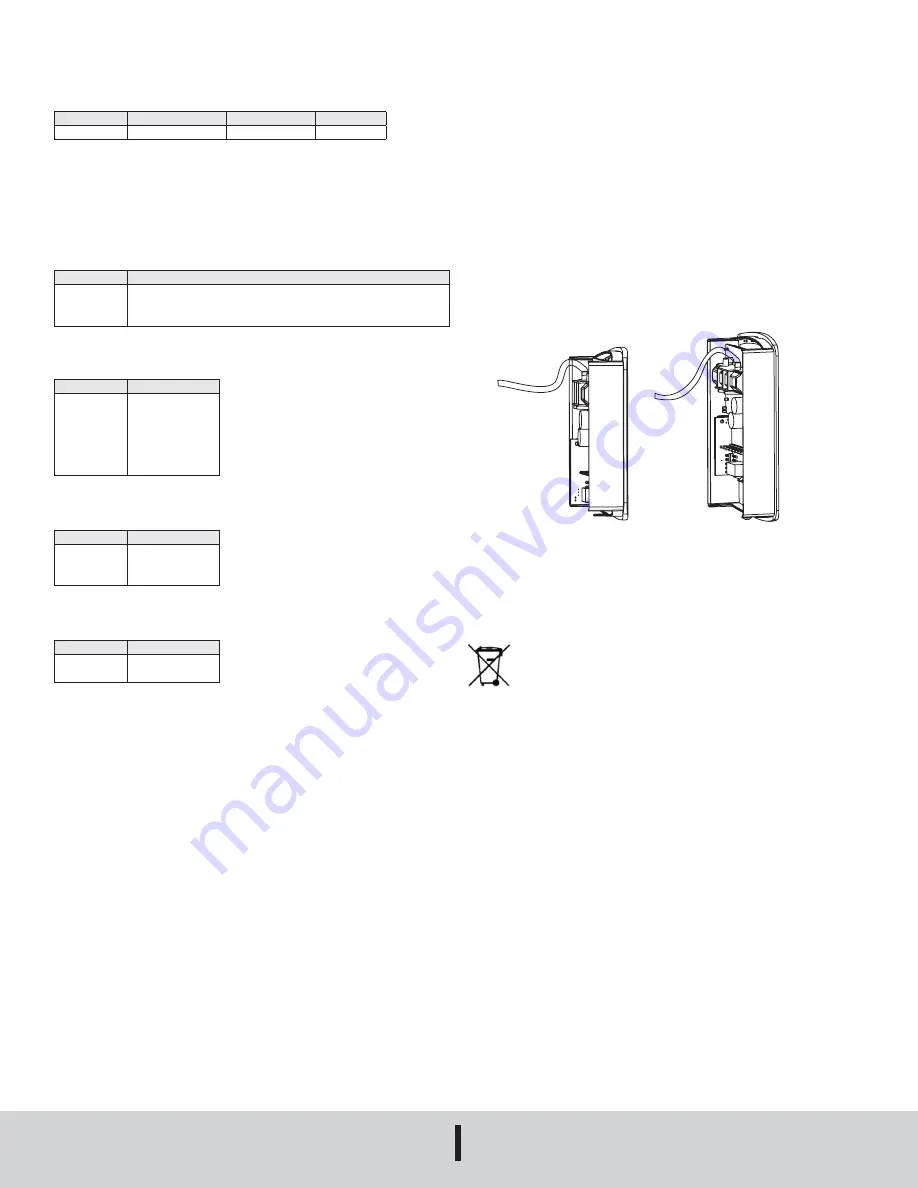

Step 1: Remove the cover as shown in Figure 1.

Step 2: Remove one of the gas nipple covers on the CO

2

sensor and attach tubing

from the gas pressure regulator to the nipple (See Figure 5).

Step 3: Attach the terminal block accessory to the circuit board so that the power wires

line up with terminals 1 and 2. Plug in the power supply to power up the

transmitter.

Step 4: Hold housing so that the sensor is in the vertical plane as shown in Figure 5.

Step 5: Follow the steps in the accessing parameter section to access the calibration

parameter (CAL).

Step 6: Press and hold the Up and Down arrows for 3 seconds.

Step 7: Flow zero reference gas at 0.3 SLPM for 5 minutes.

Step 8: Press and hold the Down button for 0.5 seconds.

Step 9: Flow the full scale reference gas at 0.3 SLPM for 5 minutes.

Step 10: Press and hold the Up button for 0.5 seconds.

Step 11: Exit the parameter menu.

Step 12: Disconnect the power supply from the power source and remove the terminal

block from the circuit board.

Step 13: Remove tubing from sensor and re-attach the gas nipple cover to the sensor.

Step 14: Re-attach the cover to the back plate.

MAINTENANCE/REPAIR

Upon final installation of the Series CDTA, no routine maintenance is required. The

Series CDTA is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

Default Value Minimum Value

Maximum Value Increment

0 PPM

-500 PPM

500 PPM

1 PPM

Setting Value Description

“ON”

“OFF

Auto baud enabled, assumes 8 data bits, no parity and 1 stop bit

Auto baud disabled, serial baud rate, parity, and stop bits must be

set manually

Setting Value Baud Rate (BPS)

9.6 K

19.2 K

38.4 K

57.6 K

76.8 K

115.2 K

9600

19,200

38,400

57,600

76,800

115,200

Setting Value Description

“NON”

“EVE”

“ODD”

No Parity

Even Parity

Odd Parity

Setting Value Description

1

2

One Stop Bit

Two Stop Bits

Figure 9: Calibration

European

North American

This symbol indicates waste electrical products should not be disposed

of with household waste. Please recycle where facilities exist. Check with

your Local Authority or retailer for recycling advice.