Model XE569S

Work

Q

A

Problem 2.

Slipping

Rev

1

2

3

Steps

1.

There are 4 factors to cause belt

slipping which can be checked by

following.

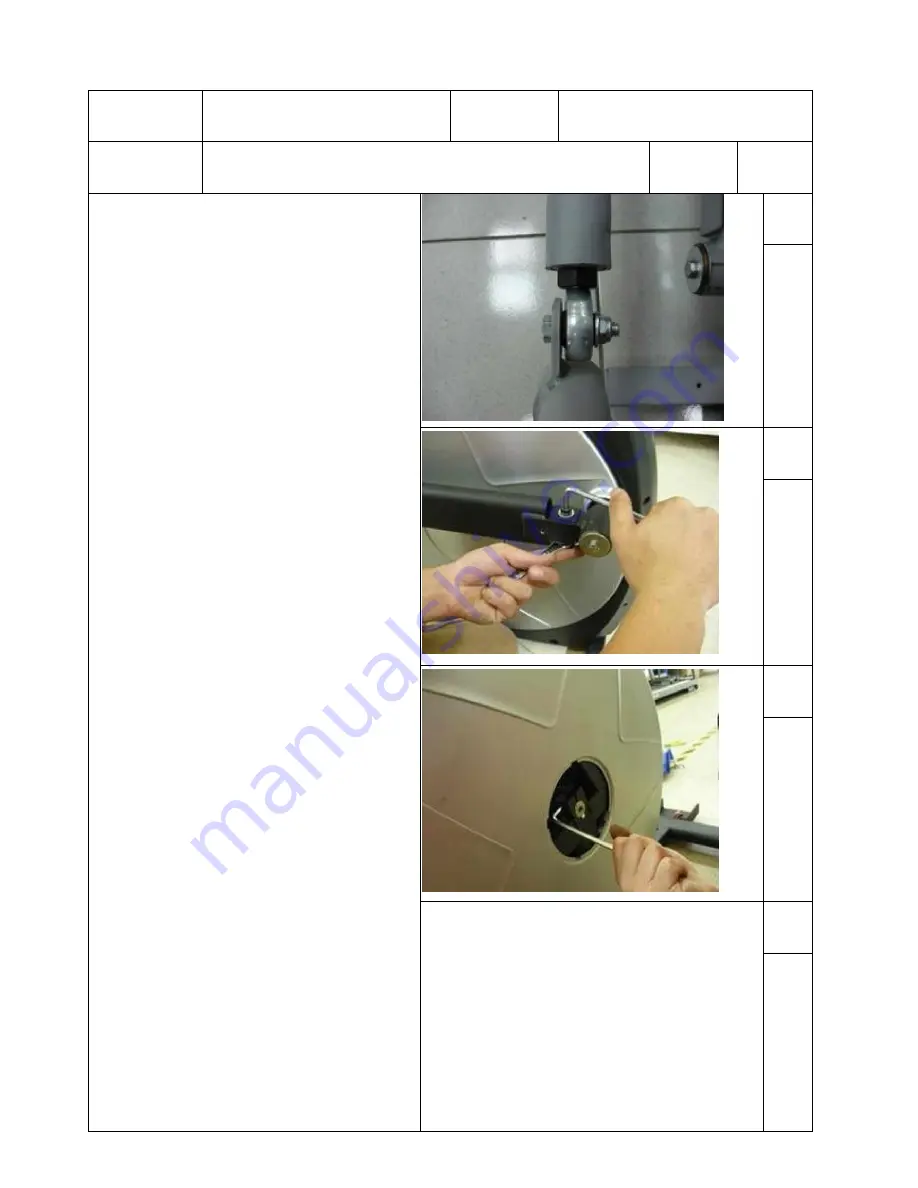

2. M12xP1.75

Rod

End

Bearing

: M12

nut on

top

of the

bearing

m

ust be

tightened

with

the

connecting

arm

.

The

M12xp1.75

Rod

End

Bearing

should

beperpendicular

to

the

floor,

as

shown

in

figure

1.

.

3. Bushing Housing: The 3/8" x2-1/4"

socket head cap Bolt on top and the

3/8" x11T nyloc nut on the bottom must

be tight. Suggested applying torque is

between 500~600lbs range, as show in

figure 2.

4. Cross Bar: the M8x30m/m socket head

cap bolt on the cross bar must be tight.

Suggested applying torque is between

550~600lbs range, As show in figure 3.

5.

Belt: This is a com

m

on problem

. Due

to

the

long

running

tim

e, belt usuallygets

looser

depending

on

the

tim

e and the way the unit

has

been

used, and

the

user weight. Follow

the

belt

assem

bling/disabling

steps,

procedure

4, to

m

ake

adjustm

ent.